Corporate Renewable Procurement for Manufacturing Plants

Cost Savings and Efficiency Gains

The financial case for renewables has never been stronger. While fossil fuel prices swing unpredictably, renewable energy costs continue their steady decline. Forward-thinking manufacturers are locking in decades of predictable energy expenses, insulating themselves from market volatility. The efficiency gains are equally compelling—modern renewable systems often outperform traditional energy in both output and reliability.

Initial investments, while substantial, pay dividends through reduced operational costs and improved production uptime. Many companies are discovering that renewable infrastructure pays for itself faster than anticipated, thanks to advancing technologies and creative financing options.

Supply Chain Sustainability

Today's manufacturers don't operate in isolation. Their energy choices reverberate through entire supply networks. By adopting renewables, companies create cascading effects, pressuring suppliers to follow suit or risk losing business. This creates a virtuous cycle of sustainability that strengthens the entire production ecosystem.

The benefits extend beyond environmental impact. More sustainable supply chains prove more resilient, weathering disruptions that might cripple traditional operations. In an era of climate uncertainty, this resilience translates directly to competitive advantage.

Technological Advancements and Innovation

The renewable revolution is accelerating at breakneck speed. Solar panels today generate twice the power of models from a decade ago at half the cost. Wind turbines now harness breezes that would have been uneconomical just years ago. These aren't incremental improvements—they're game changers making renewables the smart choice for cost-conscious manufacturers.

This innovation extends beyond energy production. Manufacturers are redesigning processes specifically for renewable integration, creating entirely new approaches to production that would have been impossible with traditional energy sources.

Regulatory and Policy Support

Governments worldwide are stacking the deck in renewables' favor. From tax incentives to streamlined permitting, the policy landscape increasingly rewards sustainable manufacturers. Companies that move quickly can capitalize on these benefits, while laggards may face penalties and restrictions.

The smartest manufacturers aren't just complying with regulations—they're helping shape them, positioning themselves as leaders in the new energy economy.

Public Perception and Corporate Social Responsibility

Consumer attitudes have reached a tipping point. Two-thirds of buyers now consider sustainability when making purchases, and that number grows annually. Manufacturers embracing renewables aren't just saving the planet—they're capturing market share from slower-moving competitors.

This shift represents more than marketing—it's fundamental to maintaining social license to operate. In the age of social media scrutiny, sustainability performance can make or break brands overnight.

Defining Corporate Renewable Procurement for Manufacturing

Understanding the Core Concept

Corporate renewable procurement represents a seismic shift in how manufacturers power their operations. It's not about buying energy—it's about investing in long-term viability. The most sophisticated programs combine direct renewable installations with power purchase agreements and renewable energy credits.

The smartest companies treat energy procurement as a strategic function rather than a utility expense. They're building teams that understand both kilowatt-hours and corporate strategy, creating energy plans that align with broader business objectives.

The Benefits Beyond the Environment

The financial upside often surprises traditional manufacturers. Renewable contracts frequently beat conventional energy on price, especially when factoring in long-term stability. Manufacturers using renewables report fewer production disruptions and more predictable operating costs.

Perhaps most surprisingly, renewable procurement can improve access to capital. Sustainability-linked loans and green bonds offer favorable terms to companies demonstrating environmental leadership.

Types of Renewable Energy Sources

Location dictates opportunity in renewable procurement. Sunbelt manufacturers increasingly turn to solar, while those in windy regions favor turbines. The real innovation comes in hybrid systems that combine multiple renewable sources with storage solutions.

Emerging technologies like green hydrogen and advanced geothermal promise to expand options further. Manufacturers should maintain flexibility to incorporate new solutions as they become viable.

Integration Strategies for Existing Infrastructure

Transitioning legacy facilities requires careful planning. The most successful implementations start with comprehensive energy audits, identifying both quick wins and long-term projects. Many find that efficiency upgrades complement renewable installations, creating compounding benefits.

Smart manufacturers phase transitions to minimize disruption, often starting with pilot projects before scaling successful approaches across operations.

Compliance and Regulatory Considerations

The regulatory landscape varies dramatically by jurisdiction. Leading manufacturers develop centralized expertise to navigate this complexity, ensuring they maximize incentives while maintaining compliance.

Proactive companies monitor legislative developments, positioning themselves to capitalize on new programs before competitors.

Measuring and Reporting Progress

What gets measured gets managed. The most effective programs establish clear KPIs tracking not just energy sourcing but overall carbon impact. Third-party verification adds credibility to sustainability claims.

Transparent reporting builds trust with stakeholders while identifying areas for improvement. Many manufacturers find that public commitments create helpful accountability.

Challenges and Future Trends

While upfront costs remain a barrier, innovative financing models are emerging. Energy-as-a-service arrangements allow manufacturers to adopt renewables with minimal capital outlay.

The future points toward microgrids and distributed generation, giving manufacturers unprecedented control over their energy destiny. Those who adapt quickest will reap the greatest rewards.

Key Benefits of Renewable Energy Procurement for Manufacturers

Reduced Operational Costs

The financial benefits of renewables extend far beyond simple energy savings. Modern renewable systems require less maintenance than traditional power infrastructure, reducing ongoing expenses. Many manufacturers report improved equipment longevity when paired with clean energy.

Perhaps most importantly, renewable procurement protects against future price shocks. While fossil fuel costs fluctuate wildly, renewable agreements offer decades of price certainty.

Enhanced Brand Reputation and Stakeholder Engagement

In today's market, sustainability is table stakes. Manufacturers leading in renewables enjoy preferential treatment from eco-conscious buyers, often commanding premium pricing. Employee recruitment and retention improve markedly among sustainability leaders.

Investors increasingly screen for environmental performance, making renewable adoption critical for capital access. The reputational benefits extend to community relations and regulatory dealings.

Improved Regulatory Compliance and Risk Mitigation

Environmental regulations grow stricter annually. Early adopters of renewables avoid costly retrofits and compliance headaches down the road. They're also better positioned to capitalize on emerging carbon markets.

Renewable energy diversifies risk, reducing vulnerability to supply disruptions and geopolitical instability affecting traditional energy markets.

Access to Innovative Technologies and Research

Renewable procurement opens doors to cutting-edge innovations. Manufacturers partnering with energy providers gain early access to breakthroughs in storage, smart grids, and efficiency technologies.

These collaborations often yield unexpected benefits, from waste heat recovery to advanced materials with renewable applications.

Increased Operational Efficiency and Productivity

The reliability of renewable systems translates directly to production floor performance. Manufacturers report fewer disruptions and more consistent output with renewable-powered operations.

Improved workplace environments—from better air quality to temperature stability—further enhance productivity. The operational benefits often exceed the direct energy savings.

Strategies for Successful Renewable Energy Procurement

Harnessing Solar Power for a Sustainable Future

Solar adoption requires customized solutions—what works for a Texas factory won't suit a Michigan plant. The most successful implementations combine rooftop arrays with offsite power purchase agreements, optimizing for both space and economics.

Advanced monitoring systems maximize output, while creative financing like solar leases make adoption accessible. The key is treating solar as a strategic asset rather than a compliance exercise.

Wind Energy: A Powerful Force for Change

For manufacturers in windy regions, turbines offer compelling returns. The latest direct-drive designs require minimal maintenance while delivering more consistent output. Offshore options, while capital-intensive, provide unmatched scale.

Smart manufacturers combine wind with other renewables, creating resilient hybrid systems. Community wind projects can offer additional benefits through local partnerships.

Hydropower's Enduring Role in Renewable Energy

While large dams face environmental concerns, small-scale hydro presents untapped potential. Manufacturers near waterways can leverage modern micro-hydro systems with minimal ecological impact.

Pumped storage solutions help address intermittency, making hydropower a key piece of comprehensive renewable strategies.

Geothermal Energy: Tapping into Earth's Heat

Geothermal remains underutilized despite its reliability. New drilling technologies are making geothermal viable in more locations than ever before. Manufacturers should evaluate both electricity generation and direct-use applications.

The consistent baseload power makes geothermal particularly valuable for continuous process industries.

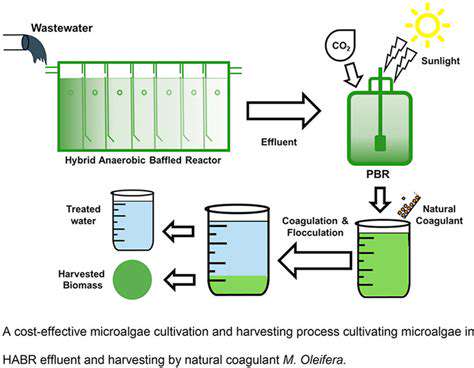

Bioenergy: Utilizing Organic Resources

Waste-to-energy solutions turn liabilities into assets. Advanced biogas systems can process various waste streams, from agricultural byproducts to manufacturing residuals. The key is matching feedstock availability with appropriate conversion technologies.

Closed-loop bioenergy systems create circular economies, reducing both waste disposal costs and energy expenses.

Integrating Renewable Energy into Existing Infrastructure

Successful integration requires holistic planning. Start with energy mapping to identify synergies between renewable sources and production needs. Smart inverters and advanced controls optimize renewable utilization.

Consider both physical upgrades and workforce training to maximize system performance. The most effective transitions balance ambition with operational reality.

Measuring and Reporting on Sustainability Impact

Defining Sustainability Metrics

Effective measurement starts with materiality—focus on impacts that matter most to your business and stakeholders. Carbon intensity, renewable penetration, and circularity metrics form the foundation.

Leading manufacturers adopt science-based targets aligned with global climate goals, ensuring their efforts contribute meaningfully to broader sustainability objectives.

Data Collection and Analysis Procedures

Automated monitoring systems transform sustainability reporting. IoT-enabled sensors provide real-time visibility into energy flows, emissions, and resource use. Cloud-based platforms aggregate data across facilities.

Advanced analytics identify inefficiencies and improvement opportunities, turning raw data into actionable insights.

Reporting on Sustainability Progress

Modern sustainability reports tell compelling stories. Interactive dashboards allow stakeholders to explore data relevant to their interests. Case studies highlight tangible impacts beyond numbers.

The most effective reports connect sustainability performance to business value, demonstrating how environmental leadership drives financial results.

Stakeholder Engagement and Communication

Sustainability communication must be as sophisticated as the initiatives themselves. Tailor messages to different audiences—investors want ROI data, while communities care about local impacts.

Regular sustainability briefings keep stakeholders informed and engaged. Two-way communication channels ensure feedback informs continuous improvement.