Green Hydrogen for Industrial Decarbonization: Steel, Ammonia, and Chemicals

Revolutionizing Steel Production with Green Hydrogen

The Promise of Clean Steelmaking

The steel industry stands at a crossroads as it explores green hydrogen's transformative potential. Unlike conventional methods that depend on carbon-intensive processes, this innovative approach leverages renewable-powered electrolysis to create hydrogen without harmful emissions. This breakthrough could slash the sector's carbon footprint by up to 95%, making it a game-changer for heavy industry. The environmental benefits are particularly compelling given steel's status as one of the world's most carbon-polluting industries.

Environmental Toll of Conventional Steel Production

Traditional blast furnaces consume vast quantities of coking coal, releasing approximately two tons of CO₂ for every ton of steel produced. This staggering emission profile has forced the industry to urgently seek alternatives. The shift toward hydrogen-based direct reduced iron (DRI) technology represents more than just an environmental imperative - it's becoming an economic necessity as carbon pricing mechanisms expand globally.

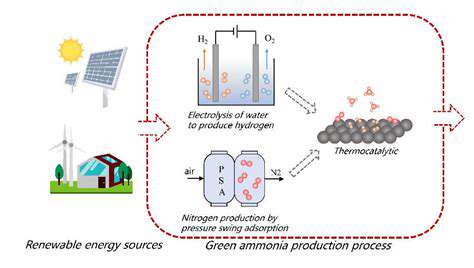

How Electrolysis Enables Clean Hydrogen Production

At the heart of this transformation lies electrolyzer technology, which uses renewable electricity to split water molecules. When powered by wind or solar installations, the process creates truly green hydrogen with near-zero emissions. Recent advancements in proton exchange membrane (PEM) electrolyzers have improved efficiency to 75-80%, making the technology increasingly viable for industrial applications. This technological progress is crucial for scaling up production to meet steelmakers' massive hydrogen demands.

Implementation Hurdles and Solutions

Transitioning to hydrogen-based steel production presents multiple challenges that require strategic solutions:

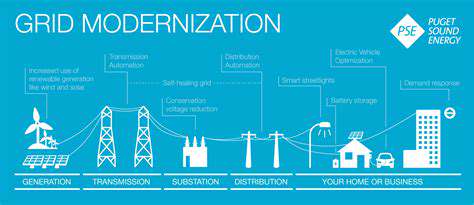

- Infrastructure costs for renewable energy projects and electrolysis facilities

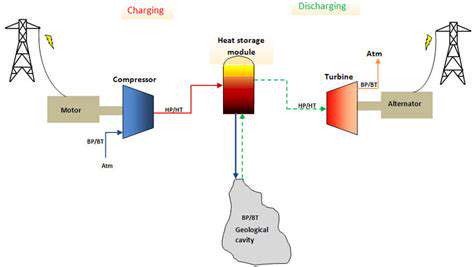

- Intermittency of renewable power sources requiring innovative storage solutions

- Technical adaptations needed in existing steel plants

Strategic investments and policy support are helping overcome these barriers, with several pilot projects demonstrating technical feasibility across Europe and Asia.

Synergies with Carbon Management Technologies

While green hydrogen offers the cleanest path forward, carbon capture systems can serve as an important transitional technology. Modern CCU installations can capture 85-90% of process emissions, though they shouldn't be viewed as a long-term substitute for complete decarbonization. The most forward-looking steel producers are exploring hybrid systems that combine both approaches during the industry's transition period.

Green Hydrogen's Impact on Ammonia Production

Transforming Fertilizer Manufacturing

The $70 billion global ammonia industry consumes about 2% of world energy production, predominantly from fossil sources. Green hydrogen changes this equation dramatically by enabling carbon-free ammonia synthesis through the Haber-Bosch process. This shift could eliminate nearly 500 million tons of annual CO₂ emissions from fertilizer production alone. Several European chemical companies have already begun converting facilities to run on renewable hydrogen, with commercial-scale plants expected by 2026.

Economic and Technical Considerations

The transition faces several economic challenges that require innovative solutions:

| Challenge | Emerging Solution |

|---|---|

| High electrolyzer costs | Mass production reducing unit costs by 40-60% |

| Renewable energy variability | Advanced battery and hydrogen storage systems |

| Infrastructure gaps | Hybrid hydrogen-ammonia transport solutions |

Government incentives like the EU's Innovation Fund and US Inflation Reduction Act are accelerating commercialization, with project pipelines growing exponentially.

Expanding Applications in Chemical Manufacturing

Beyond Ammonia: New Industrial Applications

Green hydrogen is finding diverse applications across the chemical sector:

- Methanol synthesis for plastics production

- Refinery hydrocracking processes

- Specialty chemical manufacturing

The integration of AI in renewable energy systems is particularly promising for optimizing these hydrogen-dependent processes. Machine learning algorithms can dramatically improve electrolyzer efficiency and predict maintenance needs, reducing operational costs.

Scaling Challenges and Policy Frameworks

Widespread adoption faces several systemic barriers that require coordinated solutions:

- Standardization of safety protocols for hydrogen handling

- Development of international trade frameworks for green molecules

- Workforce retraining programs for the energy transition

Forward-thinking nations are implementing comprehensive hydrogen strategies that address these challenges holistically. South Korea's Hydrogen Economy Roadmap and Germany's National Hydrogen Strategy exemplify this integrated approach, combining R&D funding with market incentives and infrastructure planning.

The Path Forward

The coming decade will be decisive for green hydrogen's industrial adoption. As costs continue falling and policy support strengthens, we're approaching the tipping point where green solutions become economically preferable to conventional methods. The industries that embrace this transition earliest will secure competitive advantage in the low-carbon economy of the future. With continued innovation and collaboration across sectors, green hydrogen can fulfill its promise as the cornerstone of sustainable industry.