Understanding Different Energy Storage Technologies

Compressed Air Energy Storage (CAES): Harnessing the Power of Air

Compressed Air Energy Storage (CAES): A Powerful Solution

In today's energy landscape, compressed air energy storage has emerged as one of the most practical solutions for addressing renewable energy intermittency. This innovative approach utilizes compressed air stored in underground formations to balance electricity supply and demand. The simplicity of this concept belies its transformative potential for grid stability.

The operational mechanics involve two distinct phases. During surplus renewable generation, electric compressors force air into geological formations at pressures exceeding 70 bar. When grid operators require additional power, this pressurized air gets released through turbines, generating electricity precisely when it's needed most. This cyclic process effectively creates a massive energy buffer that can be tapped on demand.

Harnessing the Potential of Underground Reservoirs

What makes this technology particularly appealing is its ability to repurpose existing underground spaces. Abandoned hydrocarbon reservoirs and salt caverns, once considered liabilities, now represent valuable energy storage assets. This adaptive reuse approach significantly reduces both capital expenditures and environmental impacts compared to building new surface facilities.

Geological suitability remains paramount for successful implementation. Engineers conduct comprehensive evaluations of potential sites, analyzing rock porosity, structural integrity, and hydrological conditions. Only formations demonstrating exceptional containment characteristics receive approval for compressed air storage applications. Rigorous monitoring systems ensure ongoing operational safety and prevent any potential leakage.

Technological Advancements and Efficiency Improvements

The field continues to benefit from significant engineering breakthroughs. Modern compressors now achieve adiabatic efficiencies exceeding 80%, while advanced turbine designs minimize energy losses during power generation. These cumulative improvements have enhanced round-trip efficiency from below 50% to nearly 70% in next-generation systems.

Material science innovations deserve particular recognition. New composite materials for pressure vessels and specialized coatings for turbine blades dramatically extend equipment lifespans. These developments have reduced maintenance requirements while simultaneously improving system reliability. Ongoing research promises even greater efficiency gains in coming years.

Environmental Considerations and Sustainability

Environmental stewardship remains central to CAES deployment strategies. Operators implement multiple safeguards, including real-time pressure monitoring and automated shutoff systems, to prevent any subsurface impacts. Regular integrity testing ensures storage formations maintain their containment capabilities throughout decades of operation.

The sustainability profile improves dramatically when paired with renewable energy. When compression power comes from wind or solar sources, the entire system achieves near-zero operational emissions. This clean energy synergy positions CAES as a key enabler for decarbonized electricity grids worldwide.

Thermal Energy Storage: Capturing Heat and Cold

Thermal Energy Storage: A Crucial Technology

Thermal energy management represents a critical frontier in energy system optimization. This approach fundamentally transforms how we handle thermal energy flows across multiple sectors. The ability to temporally decouple heat production from consumption marks a paradigm shift in energy infrastructure design.

Practical applications demonstrate remarkable versatility. Industrial facilities use thermal reservoirs to shift process heat demands, while commercial buildings leverage phase-change materials for HVAC optimization. Perhaps most importantly, these systems enable renewable thermal sources to compete with conventional heating methods on both performance and cost.

Different Types of Thermal Energy Storage

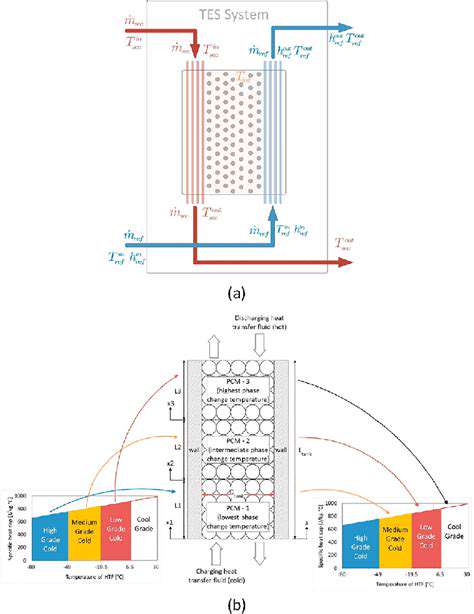

The technology spectrum encompasses several distinct approaches, each with specialized advantages. Sensible heat systems, utilizing water or molten salts, dominate large-scale applications due to their simplicity and reliability. Latent heat systems employing phase-change materials offer superior energy density for space-constrained applications.

Selection criteria extend beyond technical specifications. Engineers must consider thermal cycling stability, material degradation rates, and integration complexity. The optimal solution varies considerably depending on temperature requirements, discharge duration, and available space. Emerging hybrid systems combine multiple approaches for enhanced performance.

Applications and Benefits of Thermal Energy Storage

Industrial adoption continues to accelerate, particularly in energy-intensive sectors. Glass manufacturers utilize thermal storage to maintain furnace temperatures during production lulls, while food processors employ it for refrigeration cycle optimization. These applications typically achieve payback periods under three years, demonstrating compelling economic viability.

The broader societal impacts warrant equal consideration. By enabling greater renewable energy utilization and reducing peak demand charges, thermal storage systems significantly lower overall energy costs. This technology plays an indispensable role in achieving climate mitigation targets while maintaining industrial competitiveness. Future developments promise even greater integration across the energy value chain.