Lifecycle Emissions of Electric Vehicles Powered by Renewable Energy

End-of-Life Management and Recycling

End-of-Life Vehicle Recycling

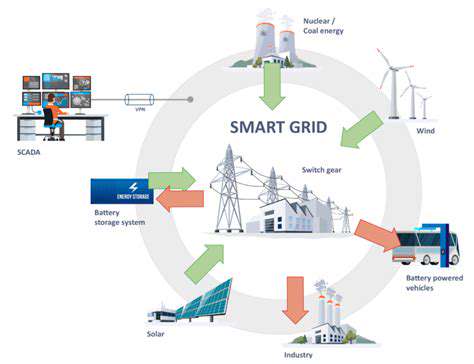

Responsible management of electric vehicles (EVs) at end-of-service is essential for environmental protection. The sophisticated components comprising EVs, including energy storage systems, propulsion units, and control electronics, demand specialized processing to recover valuable materials and mitigate hazardous waste generation. Recycling operations must employ appropriate procedures to safely disassemble and process these elements, ensuring recovery of critical materials like lithium, cobalt, and nickel for reuse in manufacturing. This practice substantially reduces the environmental impacts associated with virgin material extraction, supporting sustainable EV lifecycle management.

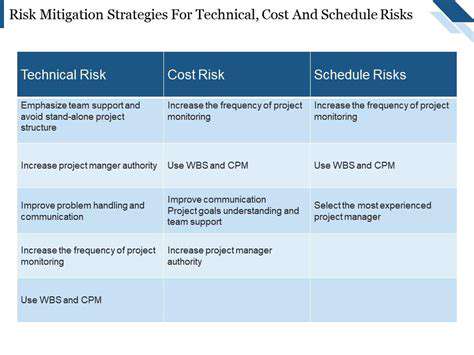

Many regions currently lack sufficient recycling infrastructure. Developing this capacity requires investment in specialized processing facilities and workforce training to handle distinctive EV component characteristics. Policy frameworks and regulatory measures play a crucial role in encouraging adoption and development of these recycling practices. Public education initiatives can promote awareness about proper EV disposal methods, motivating consumers to utilize certified recycling services.

Battery Management Strategies

EV battery systems require particular attention during end-of-life processing. Lithium-ion battery technology, while efficient for energy storage, presents environmental risks if improperly handled. Advanced techniques allow extraction and recovery of valuable metals including lithium, nickel, and cobalt from depleted battery packs. This process helps alleviate pressure on primary material sources and fosters circular economy principles for EV components.

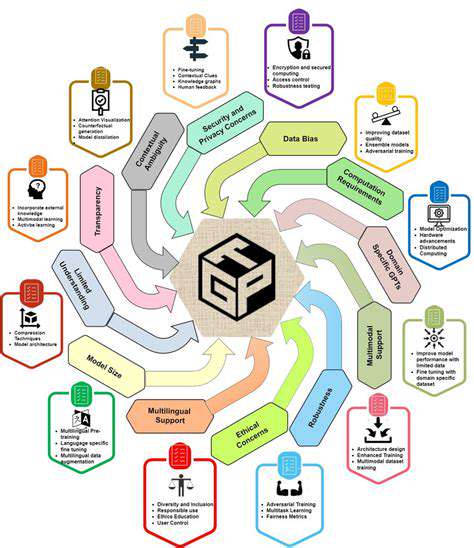

Battery recycling faces technical challenges due to complex chemical compositions. Managing these chemical processes safely and efficiently remains critical for effective material recovery. Continuous battery technology evolution necessitates ongoing adaptation of recycling methods to accommodate new material formulations. Research and technological development in this sector are vital for maintaining efficient battery recycling systems.

The diversity of battery chemistries across different EV models presents additional processing complexities. Various battery types require distinct recycling approaches, and the presence of ancillary materials like plastics and metals further complicates separation processes. Recycling facilities must implement sophisticated sorting and processing capabilities to maximize material recovery from these diverse components.

Material Recovery and Reuse

EV end-of-life management extends beyond simple disposal to encompass comprehensive material recovery and reintegration into manufacturing streams. Salvaged materials from EV components, including battery systems, motors, and electrical wiring, can be repurposed for new part production or incorporated into alternative products, reducing demand for virgin materials. This approach supports sustainable, circular economic models that minimize the ecological footprint of EV production and consumption.

Effective EV material recycling creates significant economic development opportunities. By establishing robust recycling infrastructure and developing technical expertise, nations can cultivate domestic industries focused on EV material processing and reuse. These industries contribute to employment growth and economic diversification while reducing environmental impacts.

Comprehensive material recovery and reuse strategies represent fundamental components of long-term EV industry sustainability. Prioritizing recycling and material circularity enables creation of closed-loop systems that minimize waste and optimize resource utilization. This methodology critically reduces the environmental impact of EV manufacturing and supports responsible management of electric vehicle lifecycle emissions.