Lithium Ion Battery Chemistry Advances: Beyond NMC and LFP

Lithium-Rich Cathode Innovations

Lithium-excess layered oxides represent a paradigm shift in cathode technology, offering substantially greater energy density than conventional compositions. Their flexible chemistry allows precise adjustment of electrochemical properties by modulating metal ratios. This tunability enables optimization for specific applications, yielding superior cycle life and operating voltages. Abundant constituent materials enhance their economic viability for mass production.

The complex dance of lithium and transition metal ions within the crystalline framework dictates performance characteristics. Understanding these atomic-scale interactions is crucial for developing high-performance, long-lasting cathodes. Current research focuses on stabilizing the structure during charge cycles to prevent capacity fade.

Transition Metal-Based Solutions

Novel transition metal compounds demonstrate remarkable potential for next-gen cathodes. Their unique electronic configurations enable unprecedented energy density and charge rate combinations. Strategic incorporation of elements like nickel and manganese creates tailored electrochemical profiles surpassing traditional materials.

Deciphering the fundamental electrochemistry of these systems enables smarter material design. This knowledge base supports development of cathodes with faster reaction kinetics and enhanced safety characteristics. Maintaining structural integrity during prolonged cycling remains a key research focus.

Innovative Intercalation Compounds

Phosphate and silicate-based materials are emerging as promising cathode alternatives. Their distinct chemical bonding architectures offer potential safety and energy density advantages. These unconventional compositions may outperform conventional cathode materials in next-generation battery systems.

The complex intercalation mechanisms in these materials demand thorough investigation. Understanding these processes at atomic scales will inform improved synthesis methods and material engineering approaches.

Synthesis Methodologies

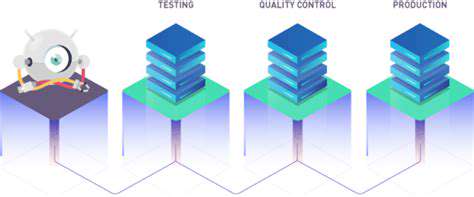

Advanced fabrication techniques enable precise control over cathode material properties. Hydrothermal and sol-gel processes produce materials with optimized microstructures for enhanced performance. These methods critically influence particle morphology, porosity, and electrochemical behavior.

Meticulous control of synthesis parameters determines the final material characteristics. Consistency in particle size and morphology proves essential for achieving reliable, high-performance cathode materials.

All-Solid-State Batteries: Overcoming Safety Challenges

Performance Enhancements

All-solid-state batteries (ASSBs) mark a safety revolution by eliminating flammable liquid electrolytes. This fundamental redesign dramatically reduces fire risks while enabling higher energy densities. Removing liquid components essentially eliminates thermal runaway scenarios that plague conventional batteries. The inherent stability of solid electrolytes creates safer energy storage solutions for sensitive applications.

Solid electrolytes enable faster charging cycles compared to liquid-based systems. Their stable ionic conduction pathways support rapid energy transfer, making ASSBs ideal for applications requiring quick power delivery.

Technical Hurdles

ASSB development faces several material science challenges. Achieving high ionic conductivity in solid materials remains a primary obstacle. Researchers must balance this requirement with mechanical stability and electrode compatibility.

The electrode-electrolyte interface presents another critical development area. Minimizing resistance at this junction is essential for optimal battery performance and longevity.

Material Innovations

Breakthroughs in ceramic and polymer electrolytes drive ASSB progress. Scientists engineer these materials to meet stringent conductivity and durability requirements. Tailoring material properties ensures seamless integration with electrode components for maximum efficiency.

Concurrently, electrode architectures evolve to optimize solid-state interactions. Surface modifications and novel designs enhance ion transport while reducing interface resistance—key factors in commercial viability.

Application Potential

ASSBs promise transformative impacts across industries. Their inherent safety makes them ideal for electric vehicles and consumer electronics. Potential applications include ultra-fast charging devices and longer-lasting portable power solutions.

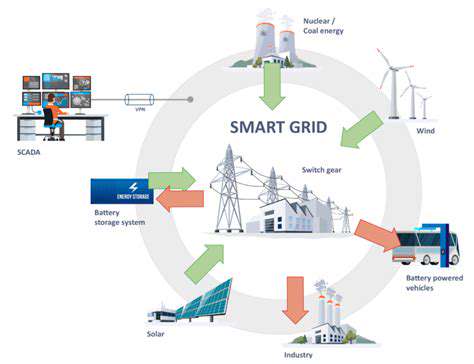

Grid-scale energy storage represents another promising application. ASSB technology could enable more efficient renewable energy integration and stabilized power networks.

The Future of Battery Chemistry: A Multifaceted Approach

Solid-State Battery Prospects

Solid-state technology represents the vanguard of energy storage innovation. By replacing liquid electrolytes with solid alternatives, these systems offer superior safety and potential energy density gains. Current research focuses on ceramic and polymer electrolytes, addressing conductivity and mechanical challenges. While promising, significant development is needed to overcome material limitations for widespread commercialization.

Electrolyte Engineering

Next-generation electrolytes aim to revolutionize ion transport efficiency. Scientists explore nanoscale modifications and additive formulations to overcome existing limitations. Advanced analytical techniques provide atomic-level insights into ion movement mechanisms, guiding smarter material design.

Electrode Material Advances

Novel electrode compositions push capacity and performance boundaries. Transition metal compounds show particular promise for energy density improvements. Precision engineering of material structures through doping and nanostructuring enhances electrochemical properties for demanding applications.

Nanotechnology Integration

Nanoscale engineering transforms battery component design. Nanomaterials enable larger active surfaces and optimized ion pathways. Their unique properties also contribute to improved safety margins and system stability, representing a powerful tool for next-generation battery development.