Offshore Wind Hybrid Project Development

Offshore wind hybrid systems represent a cutting-edge approach to harnessing renewable energy, combining the power of offshore wind turbines with other energy sources. This innovative approach promises a more reliable and sustainable energy future by addressing the intermittent nature of wind power. Understanding the diverse components and functionalities of these systems is crucial for evaluating their potential and limitations.

Key Components of Offshore Wind Hybrid Systems

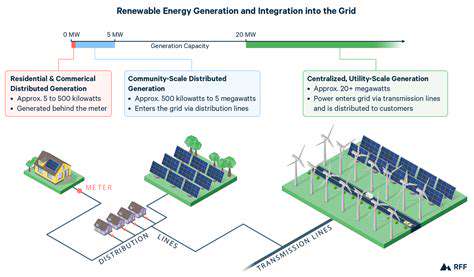

These systems typically incorporate several key components. Crucially, the wind turbines themselves are a fundamental element, providing the primary source of power. Supporting infrastructure, such as substations and transmission lines, is essential for efficiently transporting the generated electricity to the grid.

Other key components might include energy storage solutions like batteries or pumped hydro storage, enabling the system to manage fluctuations in wind speed and maintain a consistent power output. These storage mechanisms are vital for ensuring grid stability.

Advantages of Utilizing Offshore Wind Hybrid Systems

The integration of different energy sources in offshore wind hybrid systems offers several significant advantages. One key benefit is enhanced grid stability and reliability, mitigating the impact of wind power's inherent variability. The incorporation of other renewables, like solar or tidal power, can further improve the system's resilience and adaptability.

Furthermore, these systems can improve the overall efficiency of energy production. By combining various sources, the system can optimize power output and minimize waste. The utilization of diverse energy sources can reduce reliance on fossil fuels, contributing to a cleaner and greener energy landscape.

Challenges in Implementing Offshore Wind Hybrid Systems

Despite the numerous advantages, implementing offshore wind hybrid systems faces several challenges. One significant hurdle is the high upfront investment required for the construction and installation of these systems. The technical complexity of integrating diverse energy sources adds to the overall costs and time required for deployment.

Moreover, the environmental impact of these systems needs careful consideration. Potential impacts on marine ecosystems and bird migration patterns must be assessed and mitigated throughout the planning and construction phases. Successful implementation relies on careful environmental impact assessments.

Future Prospects and Research Directions

The future of offshore wind hybrid systems looks promising. Ongoing research and development are focused on improving the efficiency and cost-effectiveness of these systems. This includes exploring innovative energy storage technologies and optimizing the integration of different renewable energy sources.

Further research into the long-term environmental impacts and the potential for large-scale deployment is essential. This will pave the way for the widespread adoption of offshore wind hybrid systems as a crucial component of a sustainable energy future.

Predicting veterinary costs for animals, particularly in the long term, requires a comprehensive understanding of the factors influencing these expenses. These factors are multifaceted and often intertwined, making accurate forecasting a complex process. Initial consultations, diagnostic tests, medication, and potential surgical procedures all contribute to the overall cost, and their prices can vary significantly depending on location, the specific veterinary practice, and the animal's breed and condition. Understanding these variables is the first step towards developing a realistic and informed financial plan for pet owners.

Technological Advancements and Innovation

Technological Advancements in Manufacturing

Technological advancements are rapidly transforming the manufacturing sector, leading to increased efficiency, productivity, and innovation. Automation and robotics are playing a crucial role in streamlining production processes, reducing human error, and optimizing resource utilization. This allows manufacturers to produce goods faster, with higher quality, and at lower costs, ultimately boosting profitability and competitiveness in the global market.

The integration of advanced technologies like artificial intelligence (AI) and machine learning (ML) is further enhancing manufacturing capabilities. AI-powered systems can analyze vast amounts of data to predict maintenance needs, optimize production schedules, and improve product design, resulting in significant operational improvements.

Innovations in Materials Science

Materials science is undergoing a revolutionary phase, with the development of novel materials exhibiting enhanced properties. These new materials are pushing the boundaries of what's possible in various industries, from aerospace to construction.

The creation of lightweight, high-strength materials is transforming the automotive and aerospace sectors. This results in more fuel-efficient vehicles and aircraft, contributing to environmental sustainability. Furthermore, advancements in composite materials are enabling the creation of structures with superior performance and reduced weight.

The Rise of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the production landscape. This technology allows for the creation of complex and intricate parts directly from digital designs, eliminating the need for traditional manufacturing methods in many cases.

3D printing enables rapid prototyping and customization, empowering businesses to quickly adapt to evolving customer demands. The ability to produce customized parts on demand significantly reduces lead times and inventory costs, increasing operational efficiency.

Impact on Workforce and Skills

The integration of these technological advancements necessitates a shift in the skills required for the workforce. Traditional manufacturing jobs are evolving, demanding a greater emphasis on digital literacy, problem-solving, and adaptability. Upskilling and reskilling initiatives are crucial to ensure that the workforce can effectively navigate this technological transition.

A focus on training and education that emphasizes technical skills alongside soft skills will be essential for the future of the industry. This includes developing expertise in areas like data analysis, automation programming, and collaborative robotics.

Sustainable Manufacturing Practices

Technological advancements are driving the adoption of sustainable manufacturing practices. This involves the development of environmentally friendly processes, the use of recycled materials, and the reduction of waste. Companies are increasingly incorporating sustainability into their core strategies, recognizing the importance of minimizing their environmental footprint.

Many innovative technologies focus on reducing energy consumption, optimizing resource utilization, and minimizing waste generation in manufacturing processes, leading to a more sustainable and responsible approach.