Next Generation Offshore Wind Turbine Design and Materials

Introduction to the Evolution of Offshore Wind Turbines

Early Stages and Technological Limitations

The early days of offshore wind turbine development were characterized by significant technological hurdles. Early designs often struggled with the harsh marine environment, leading to frequent breakdowns and maintenance issues. The sheer scale of construction and the challenges of transporting and installing these massive structures offshore presented immense logistical and financial obstacles. These initial turbines, while pioneering, were less efficient and more prone to damage than modern models.

Furthermore, the availability of reliable and cost-effective materials for withstanding the corrosive marine environment was a critical constraint. This impacted the longevity and overall performance of these early systems, making them less economically viable in the long run.

Emergence of Modern Designs

Significant advancements in materials science, engineering, and manufacturing have led to the development of more robust and efficient offshore wind turbines. Modern designs incorporate advanced materials like high-strength steel alloys and composite materials, significantly increasing their durability and resilience to harsh weather conditions. These improvements have dramatically reduced maintenance requirements and extended the lifespan of the turbines.

The integration of sophisticated control systems and monitoring technologies allows for real-time data collection and analysis. Predictive maintenance strategies are employed to identify potential failures proactively, minimizing downtime and maximizing operational efficiency.

Cost Reduction Strategies

Economies of scale and innovative manufacturing techniques have been instrumental in driving down the cost of offshore wind turbine components. Standardized designs and mass production have reduced manufacturing costs, making the technology more accessible and attractive for investment.

Innovative financing models and government incentives have also played a crucial role in lowering the overall cost of offshore wind projects. These initiatives have made the technology more economically competitive with other energy sources, paving the way for wider adoption.

Technological Advancements in Turbine Components

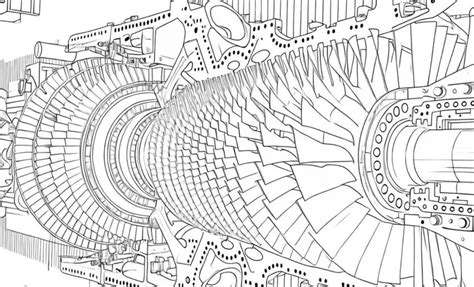

Significant progress has been made in the design and construction of turbine components, such as blades, nacelles, and foundations. Modern blades, often utilizing advanced aerodynamic designs and lighter materials, have dramatically increased energy capture efficiency. This translates directly to higher energy yields and reduced operational costs.

The nacelles, housing the critical components like generators and gearboxes, have become more compact and efficient. This translates to reduced size and weight, making transportation and installation easier and less expensive.

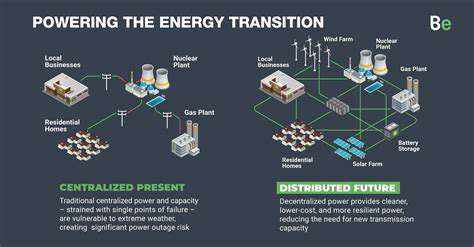

Integration with Smart Grids

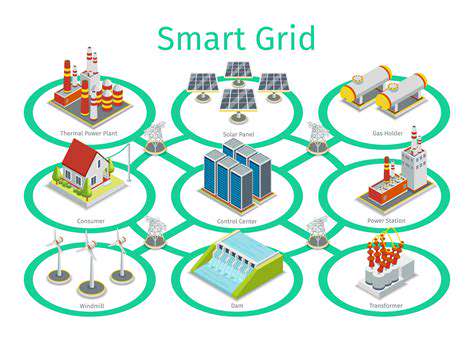

Offshore wind farms are increasingly being integrated into smart grids to optimize energy distribution and management. Smart grids facilitate the efficient transmission of renewable energy to consumers and support the integration of variable renewable energy sources like offshore wind.

Advanced grid technologies, including energy storage solutions, play a crucial role in stabilizing the electricity grid and ensuring a reliable energy supply. These developments are crucial for the seamless integration of offshore wind into the broader energy landscape.

Future Trends and Research Directions

Future research and development efforts are focusing on further optimizing turbine designs for enhanced efficiency, reduced costs, and improved environmental sustainability. Areas of active research include the exploration of floating foundations for deeper waters, the use of more advanced materials for components, and the development of more sophisticated control systems.

The ongoing pursuit of innovative technologies promises to further expand the potential of offshore wind energy, making it a truly viable and sustainable energy source for the future.

Enhanced Turbine Structures for Increased Reliability and Durability

Improved Material Selection

Modern turbine structures demand materials with exceptional high-temperature strength and resistance to creep. Advanced alloys, ceramics, and composites are being explored to withstand the extreme operating conditions of high-pressure and high-temperature environments. These materials are meticulously tested and analyzed to ensure they meet stringent performance requirements and longevity goals.

Careful consideration of material properties, such as thermal expansion and fatigue resistance, is paramount in minimizing stress concentrations and potential failure points within the turbine structure. This selection process often involves extensive simulations and real-world testing to optimize the material choice for a specific turbine design.

Optimized Design Geometry

Advanced computational fluid dynamics (CFD) simulations are essential for optimizing the geometry of turbine blades and vanes. These simulations allow engineers to analyze airflow patterns, pressure distributions, and stress levels within the structure under various operating conditions.

Sophisticated computational tools are now used to refine turbine designs, leading to improved efficiency and reduced maintenance. The aim is to reduce friction and turbulence, enhancing the overall performance of the turbine.

Enhanced Cooling Strategies

Implementing sophisticated cooling strategies is crucial for maintaining the integrity of turbine components at high temperatures. These strategies can involve internal cooling channels, film cooling, and transpiration cooling, each with its own advantages and limitations.

Advanced cooling techniques are employed to mitigate thermal stresses and ensure the longevity of the turbine components. This proactive approach to thermal management is vital for preventing premature degradation and failures of the structure.

Advanced Manufacturing Techniques

Precision manufacturing techniques play a critical role in achieving the desired structural integrity and performance of turbine components. These advanced techniques, such as laser-based additive manufacturing and directed energy deposition, enable the creation of complex geometries and intricate internal cooling channels.

Structural Integrity Monitoring

Real-time monitoring of the structural integrity of turbine components is essential for proactive maintenance and preventing catastrophic failures. This includes using sensors to track critical parameters like temperature, strain, and vibration.

Monitoring systems provide valuable data for predicting potential issues and enabling timely interventions, thus reducing downtime and maximizing operational efficiency. The insights gathered are crucial for making informed decisions about maintenance schedules and component replacement.

Advanced Computational Modeling

Advanced computational models are crucial for predicting the behavior of turbine structures under various operating conditions. These models are validated against extensive experimental data to ensure their accuracy and reliability.

Computational modeling enables engineers to test various design parameters and optimize turbine performance without the need for extensive physical prototypes, saving time and reducing development costs while improving the overall design process.

Sustainable Materials and Manufacturing

Sustainability is increasingly important in the design and manufacturing of turbine structures. This involves exploring the use of recycled materials and implementing environmentally friendly manufacturing processes.

Minimizing the environmental impact of turbine production and operation is a key consideration for the future of this crucial technology. The development of sustainable alternatives to traditional materials and processes is a significant area of ongoing research.