The Economics of Advanced Solar Technologies: A Deep Dive

Tandem Solar Cells: A Multi-Junction Approach

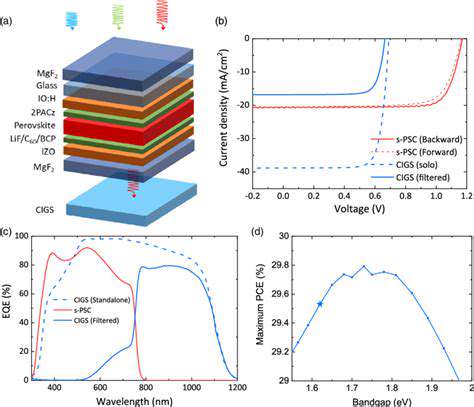

Tandem solar cells, a cutting-edge advancement in photovoltaic technology, combine two or more different solar cells with varying bandgaps to absorb a broader spectrum of sunlight. This innovative approach significantly improves the overall efficiency compared to single-junction cells by capturing photons across a wider range of wavelengths. By strategically layering materials with specific energy bandgaps, tandem cells effectively harness the full energy potential of sunlight, resulting in higher power conversion efficiencies.

The fundamental principle behind tandem solar cells lies in the complementary absorption characteristics of the constituent cells. Each individual cell within the tandem structure is optimized to absorb a specific portion of the solar spectrum. This specific absorption is determined by the bandgap of the semiconductor material used in each cell. By combining these specialized cells, tandem devices can effectively capture a greater portion of the incident solar radiation, thereby increasing the overall efficiency of the system.

Improving Efficiency and Cost-Effectiveness

One of the key benefits of tandem solar cells is their potential to significantly improve the efficiency of solar energy conversion. By capturing a wider portion of the solar spectrum, tandem cells can achieve efficiencies far exceeding those of conventional single-junction cells. This enhanced efficiency translates into a greater amount of energy generated per unit area of solar panel, making them potentially more cost-effective in the long run.

Beyond efficiency gains, tandem solar cells also offer the potential for cost reduction. The improved performance of these cells could potentially reduce the overall area needed for solar panel installations to achieve the same energy output. This is especially crucial in areas with limited space for solar energy deployment.

Material Selection and Design Considerations

The selection of materials for tandem solar cells is a critical aspect of design. Careful consideration must be given to the bandgaps of the different materials, ensuring optimal absorption across the solar spectrum. Finding suitable materials with complementary bandgaps and suitable fabrication techniques is crucial to achieve the desired performance levels. Researchers are constantly exploring new materials and fabrication techniques to enhance the efficiency and stability of these advanced solar cells.

The design of the junctions between the different cells also plays a vital role in optimizing performance. These junctions must be carefully engineered to minimize energy losses and maximize the transfer of absorbed energy throughout the system. Advanced materials science and engineering principles are required to achieve these critical performance goals.

Solar Concentrating Technologies: Harvesting Diffused Sunlight

Harnessing the Power of Diffused Light

Solar concentrating technologies are crucial for maximizing energy capture from sunlight, even when the sun isn't directly overhead. Diffused sunlight, scattered by the atmosphere, often accounts for a significant portion of the total solar irradiance, particularly in cloudy conditions. These technologies, therefore, offer a more reliable and consistent energy source compared to systems that solely depend on direct sunlight, making them particularly valuable in regions with high levels of atmospheric haze or cloud cover. This improved reliability translates into greater energy production throughout the day and year, offering a more stable power supply.

By concentrating this diffused light, these systems achieve higher energy conversion efficiencies compared to conventional flat-panel solar cells, which struggle to effectively utilize the dispersed light. This enhanced efficiency is a key economic driver, as it minimizes the overall land area required for solar power generation and reduces the capital investment needed to install the system.

Types of Concentrating Technologies

Various technologies exist for concentrating diffused sunlight, each with its own advantages and disadvantages. Parabolic trough collectors, for example, use mirrors to focus sunlight onto a receiver tube, generating heat that can be used for power generation or thermal applications. These systems are well-established and have proven reliability, but they generally require more land area for installation compared to some newer technologies.

Another approach involves using Fresnel lenses, which are a series of small, precisely shaped lenses that concentrate sunlight onto a receiver. Fresnel lenses offer a more compact design, potentially reducing installation costs, and they can be better suited for integration into building-integrated photovoltaics (BIPV) systems. However, the efficiency of Fresnel lenses can vary depending on the specific design and environmental conditions.

Materials and Manufacturing Considerations

The choice of materials for concentrators is crucial for both efficiency and cost-effectiveness. High-reflectivity materials, such as aluminum or specialized coatings, are essential for maximizing light capture. These materials must also withstand the harsh environmental conditions, such as extreme temperatures and potential corrosion, in order to maintain performance over the long term. The manufacturing processes for these concentrators influence production costs and the overall system's lifespan.

Furthermore, the manufacturing process plays a significant role in determining the durability and long-term performance of the concentrating system. Precise fabrication and quality control are paramount to ensuring that the mirrors and lenses maintain their intended shape and reflectivity over time. These factors directly influence the system's overall cost-effectiveness and long-term viability.

Economic Factors in Diffused Sunlight Utilization

The economic viability of solar concentrating technologies depends on several factors, including the cost of materials, manufacturing processes, and the overall system design. Lower material costs and optimized manufacturing processes can significantly reduce the capital investment required for installation. Additionally, government incentives and subsidies can play a crucial role in making these technologies more attractive to investors and developers.

The return on investment (ROI) for these systems is also influenced by the prevailing energy prices and the potential for energy savings. High energy costs and favorable regulatory environments can enhance the profitability of these investments. Careful economic analysis is crucial for assessing the long-term financial viability of solar concentrating systems, accounting for both upfront costs and anticipated energy generation.

Efficiency and Performance Optimization

Achieving optimal efficiency in solar concentrating systems requires careful consideration of various design parameters, including the geometry of the concentrators and the materials used. Advanced optical designs can enhance the system's ability to capture and focus diffused light, maximizing energy output. Furthermore, thermal management strategies are crucial to prevent overheating of the receiver and maintain consistent performance across a range of operating conditions.

Performance optimization also involves careful analysis of the local solar irradiance patterns and adjusting the system design accordingly. By tailoring the system to the specific solar conditions in a given location, energy production can be optimized and the system's economic viability improved. Ongoing research and development in these areas are crucial for enhancing the efficiency and cost-effectiveness of solar concentrating technologies.

Environmental Impact and Sustainability

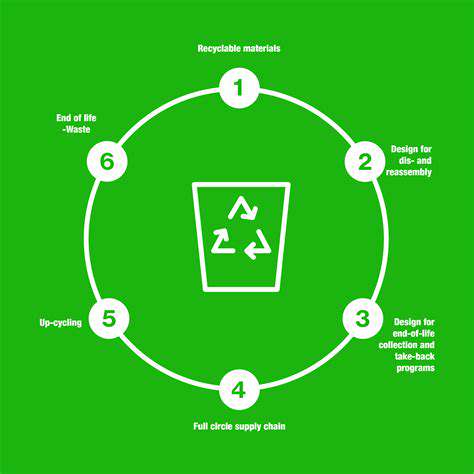

The environmental impact of these technologies is a critical consideration in their evaluation. The use of renewable resources and the reduction of reliance on fossil fuels are key aspects of their environmental benefits. The energy produced by these systems reduces greenhouse gas emissions compared to traditional energy sources, contributing to a more sustainable energy future.

Careful consideration of the manufacturing processes and material sourcing is essential to ensure the environmental sustainability of these technologies. Minimizing waste, utilizing recycled materials, and employing environmentally friendly manufacturing techniques are key to maximizing the positive environmental impact of solar concentrating technologies. These factors are increasingly important in the evaluation of long-term viability.