Perovskite Solar Energy Advancements Commercialization: Bridging the Gap

Overcoming Material Stability Issues

Understanding Material Instability

Material instability is a significant challenge in various fields, from manufacturing to energy storage. It refers to the tendency of a material to transform into a different, often less desirable, phase under certain conditions. This transformation can be driven by factors such as temperature, pressure, or the presence of impurities. Understanding the underlying mechanisms driving this instability is crucial for developing strategies to mitigate its effects and improve the performance of materials.

Identifying the specific conditions that trigger instability is paramount. This involves meticulous analysis of the material's structure and properties, along with detailed examination of the environment in which it's used. This knowledge is then used to design materials and processes that minimize the risk of unwanted transformations.

Strategies for Enhancing Stability

One crucial strategy for enhancing material stability involves optimizing the material's composition. Careful selection of constituent elements, and control over their relative proportions, can significantly impact the material's resistance to phase transformations and degradation. Adjustments to the microstructure can also be critical in improving stability, by altering the grain size, texture, or the distribution of defects.

Advanced techniques like alloying and doping can often lead to substantial improvements in material stability. These methods involve the introduction of specific elements to modify the material's electronic structure and strengthen its resistance to environmental influences.

Role of Processing Parameters

The processing parameters employed during the manufacture of a material can have a profound impact on its long-term stability. Factors such as temperature, pressure, and cooling rates during fabrication can significantly influence the microstructure, which in turn determines the material's resistance to degradation. Careful control of these parameters is often essential for achieving desired stability characteristics.

Importance of Environmental Factors

Environmental factors play a critical role in determining material stability. Exposure to moisture, oxygen, or specific chemicals can accelerate the degradation process. Understanding the influence of these external factors on the material's behavior is essential for predicting its lifespan and performance in various applications.

Environmental conditions often create significant challenges to material stability. Predicting and mitigating these impacts is a key component of material design and development.

Characterizing and Monitoring Stability

Advanced characterization techniques are essential for evaluating the stability of materials. Techniques such as X-ray diffraction, electron microscopy, and spectroscopy provide valuable insights into the material's structure and composition over time. These methods allow researchers to monitor any changes that might indicate instability and provide data for developing predictive models.

Regular monitoring of materials under operational conditions is crucial for identifying and preventing failures. Continuous assessment of the material's properties and performance helps to determine the onset of degradation and provides valuable information for extending the life of the material in service.

Applications and Future Directions

Understanding and overcoming material stability issues is critical for numerous applications, including aerospace engineering, energy storage, and biomaterials. Advancements in material science and engineering are constantly pushing the boundaries of stability, enabling the development of high-performance materials for demanding applications. This is an ongoing field of research, with continued exploration into new materials, processing techniques, and characterization methods.

Addressing material stability challenges is crucial for ensuring the reliability and longevity of various technological advancements. Further research into innovative approaches and the development of predictive models will lead to enhanced material performance and expanded applications in the future.

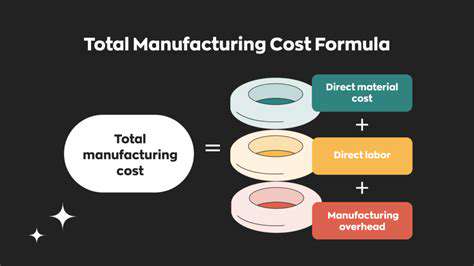

Cost-Effective Manufacturing Processes

Optimizing Material Selection

Choosing the right materials is crucial for cost-effective manufacturing. A thorough analysis of material properties, including strength, durability, and cost, is essential. Careful consideration of material availability and potential sourcing issues can also significantly impact the overall manufacturing budget. Identifying substitute materials with comparable performance characteristics but lower costs can be a key strategy for reducing production expenses.

Exploring sustainable and recycled materials is another important aspect. These alternatives can often offer a lower price point while minimizing environmental impact. Evaluating the long-term cost of materials, encompassing factors like maintenance and potential replacements, is vital for informed decision-making.

Streamlining Production Processes

Efficient production processes are fundamental to cost-effective manufacturing. Implementing lean manufacturing principles, such as eliminating waste and optimizing workflows, can drastically reduce production costs. This often requires a detailed analysis of current procedures to identify bottlenecks and areas for improvement.

Automation of repetitive tasks can significantly increase production speed and reduce labor costs. Exploring different automation technologies, from simple robotic arms to complex automated assembly lines, can greatly impact the bottom line. This allows for increased output with consistent quality, further contributing to cost-effectiveness.

Utilizing Advanced Manufacturing Technologies

Adopting advanced manufacturing technologies, such as 3D printing and additive manufacturing, can offer significant cost savings in specific applications. These technologies can facilitate rapid prototyping and customized production runs, potentially reducing tooling and material costs. Moreover, their ability to create complex geometries with minimal material waste contributes to cost optimization.

Advanced analytics and machine learning algorithms can also be employed to optimize production processes. By analyzing data from various sources, these technologies can identify patterns, predict potential issues, and recommend improvements, leading to streamlined operations and reduced waste.

Improving Supply Chain Management

A robust and efficient supply chain is essential for cost-effective manufacturing. Managing supplier relationships effectively and negotiating favorable terms can significantly impact input costs. This includes factors such as delivery times, quality assurance measures, and potential risks associated with supply disruptions.

Diversifying suppliers can help mitigate risks associated with relying on a single source. Building strong relationships with multiple reliable suppliers can provide greater flexibility and leverage in negotiation, leading to better pricing and potentially reducing lead times.

Implementing Quality Control Measures

Implementing robust quality control measures early in the manufacturing process can minimize costly rework and scrap. By proactively identifying and addressing defects, companies can reduce waste and improve overall efficiency. This includes the use of various testing methods and quality standards to ensure consistently high-quality products.

Investing in quality control equipment and training personnel on quality standards can significantly reduce defects and enhance product reliability. This proactive approach significantly reduces the overall cost of production by minimizing waste, rework, and potential returns.

Managing Inventory Effectively

Effective inventory management is crucial for minimizing storage costs and preventing obsolescence. Implementing just-in-time inventory systems can reduce warehousing needs, decrease storage costs, and prevent the accumulation of obsolete stock. This approach ensures that materials are available when needed and reduces the risk of spoilage or deterioration.

Accurate forecasting and demand planning are essential elements of effective inventory management. By anticipating future demand, companies can optimize their inventory levels, avoiding stockouts and minimizing unnecessary holding costs. This proactive approach to forecasting can significantly reduce the overall cost of inventory management.

Employee Training and Skill Development

Investing in employee training and skill development is vital for improving productivity and efficiency. A well-trained workforce is better equipped to handle complex tasks, identify potential problems, and contribute to a more cost-effective manufacturing process. This includes training programs that enhance employee skills and knowledge in areas such as process optimization, quality control, and safety procedures.

Encouraging continuous learning and development among employees can foster a culture of innovation and improvement. This creates a skilled workforce capable of adapting to changing market demands and technological advancements, ultimately contributing to a more cost-effective and sustainable manufacturing operation.