The Engineering Marvels of Offshore Wind Turbines

Understanding the Offshore Environment

Offshore wind turbines, towering giants of the energy sector, face a unique set of challenges in their foundation design. The harsh and dynamic marine environment, characterized by powerful waves, strong currents, and fluctuating water depths, necessitates a robust and resilient anchoring system. Careful consideration of these environmental factors is paramount to ensuring the longevity and structural integrity of these vital energy producers.

Analyzing the specific conditions of each offshore site, including wave patterns, seabed composition, and potential seismic activity, is crucial for selecting the appropriate foundation type. This detailed analysis allows engineers to design a foundation that effectively withstands the forces exerted on the turbines, preventing structural damage and ensuring operational stability.

Foundation Types: Tailored Solutions

Different foundation types are employed depending on the specific project requirements and the characteristics of the seabed. Monopiles, which are large, single piles driven deep into the seabed, are often used in relatively shallow waters. Jacket structures, which consist of a series of vertical columns connected by beams, are suitable for deeper water conditions, offering a more robust solution to withstand greater water pressure and wave forces.

More recently, floating foundations, such as spar buoys and tension leg platforms, have emerged as viable alternatives for even deeper waters. These designs offer unique advantages in terms of installation and cost-effectiveness, though they introduce their own set of engineering considerations, such as mooring systems and dynamic positioning.

Geotechnical Investigations: Laying the Groundwork

Accurate geotechnical investigations are essential for determining the properties of the seabed and ensuring the foundation's stability. These investigations involve drilling cores, conducting soil tests, and analyzing the seabed's composition and strength characteristics. Understanding the soil's bearing capacity, shear strength, and potential for liquefaction is vital for designing a foundation that can effectively transfer the load from the turbine to the seabed.

Material Selection: Strength and Durability

The materials selected for constructing the foundation must possess exceptional strength and durability to withstand the relentless forces of the marine environment. Steel, reinforced concrete, and specialized alloys are often used, each with unique advantages and disadvantages in terms of cost, corrosion resistance, and structural capacity. Proper material selection is critical for long-term performance and minimizing maintenance needs.

Careful consideration must be given to the potential for corrosion, particularly in saltwater environments. Protective coatings, specialized alloys, and regular inspections are crucial to prevent material degradation and maintain the foundation's integrity over the turbine's lifespan. The selection process involves a complex trade-off between cost, performance, and durability.

Installation Procedures: Precision and Safety

Installing offshore wind turbine foundations requires meticulous planning and execution. Specialized vessels and equipment are employed for tasks such as pile driving, concrete pouring, and structural assembly. Strict adherence to safety protocols and environmental regulations is crucial to minimize risks during the installation process and protect marine ecosystems.

Precise positioning and anchoring techniques are paramount to ensure the foundation's stability and prevent any unwanted movement that could jeopardize the turbine's structural integrity. Advanced monitoring systems are often deployed to track the foundation's performance and identify any potential issues during and after installation.

Monitoring and Maintenance: Ensuring Longevity

Post-installation monitoring is crucial to assess the foundation's performance and identify any signs of distress. Regular inspections and data analysis help engineers detect early warning signs of potential problems, such as settlement, corrosion, or changes in the seabed conditions. This proactive approach allows for timely interventions and ensures the long-term operational safety and efficiency of the offshore wind turbine.

Proactive maintenance strategies are vital to extend the lifespan of the foundation. This includes implementing appropriate corrosion control measures, conducting routine inspections, and addressing any observed structural issues. These measures help maintain the structural integrity and operational efficiency of the foundation, ultimately contributing to the overall success of the offshore wind farm.

Future Developments in Offshore Wind Technology

Offshore Wind Turbine Technology Advancements

Future developments in offshore wind turbine technology promise significant improvements in efficiency and cost-effectiveness. Expect to see a rise in the use of larger turbines with higher capacity factors, enabling greater energy generation from smaller footprints. This will be crucial in maximizing the potential of offshore wind farms and reducing the overall cost per unit of energy produced. Furthermore, advancements in materials science and manufacturing techniques will lead to lighter, more durable turbine components, reducing maintenance needs and improving longevity.

Innovations in blade design are also poised to play a key role. Improved aerodynamics and structural integrity will translate to enhanced performance in extreme weather conditions, making offshore wind farms more resilient and reliable. This resilience is essential for ensuring consistent energy output, a critical factor in grid integration and power supply stability.

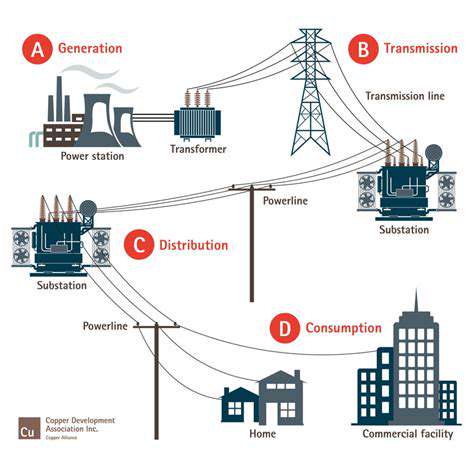

Enhanced Grid Integration and Transmission

Successfully harnessing the power of offshore wind requires robust and efficient grid integration and transmission infrastructure. The development of advanced grid technologies, including high-voltage direct current (HVDC) transmission systems, will be essential for efficiently transporting electricity generated offshore to the mainland. These systems will overcome the challenges of long distances and variable energy output, ensuring a reliable and stable power supply. This infrastructure development is critical for the widespread adoption of offshore wind energy.

Furthermore, improved forecasting and control systems will be crucial in managing the variability of wind resources. Sophisticated algorithms and data analytics will enable better predictions of wind patterns, enabling grid operators to adjust power generation and consumption to match supply and demand. This enhanced grid flexibility is essential for seamlessly integrating offshore wind energy into the existing power systems.

Environmental Considerations and Sustainability

As offshore wind farms expand, stringent environmental considerations will be paramount. Future developments must prioritize minimizing the impact on marine ecosystems, ensuring the safety of marine life, and mitigating potential noise and visual pollution. This approach will be critical to gaining public acceptance and ensuring the long-term sustainability of these projects. Careful environmental impact assessments and the implementation of mitigation strategies will be vital.

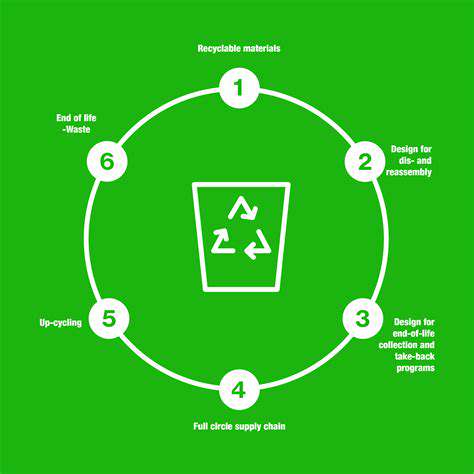

Furthermore, the recyclability and reusability of turbine components will be a critical factor in the long-term sustainability of offshore wind energy. Designing for disassembly and efficient material recovery will reduce waste and contribute to a circular economy model. This will be essential for minimizing the environmental footprint of the entire lifecycle of offshore wind power production.