The Role of IoT in Decentralization of Energy Generation Systems: Real Time Data

Real-time Data Streams for Informed Decisions

The Internet of Things (IoT) empowers businesses and individuals with unprecedented access to real-time data. This constant flow of information, gathered from interconnected devices, allows for a dynamic understanding of processes, customer behavior, and environmental factors. By analyzing these real-time data streams, organizations can make quicker, more informed decisions, optimize operations in real-time, and react to changes in the market or environment with greater agility. This immediate feedback loop is crucial for achieving operational excellence and maintaining a competitive edge.

Imagine a manufacturing facility monitoring equipment performance in real time. Sensors on machinery detect subtle deviations from optimal operating parameters. This data, transmitted and analyzed instantly, triggers preventative maintenance actions, minimizing downtime and maximizing output. This proactive approach to problem-solving is a significant advantage enabled by the IoT's real-time data collection capabilities.

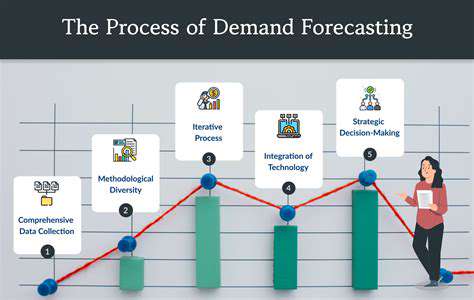

Predictive Analytics for Enhanced Efficiency

Beyond real-time monitoring, IoT data facilitates advanced predictive analytics. By identifying patterns and correlations within the vast datasets collected, businesses can anticipate future trends and potential issues. This predictive capability is invaluable for optimizing resource allocation, minimizing risks, and proactively addressing potential problems. For example, a retail store might use data from smart inventory management systems to predict demand fluctuations, ensuring optimal stock levels and minimizing waste.

Predictive maintenance, a key application of IoT, allows businesses to anticipate equipment failures before they occur. Sensors on machinery collect data on temperature, vibration, and other parameters. Sophisticated algorithms analyze these data points, identifying patterns that indicate potential malfunctions. This enables proactive maintenance schedules, reducing costly downtime and increasing equipment lifespan.

Improved Operational Efficiency and Cost Reduction

The collection and analysis of real-time data from IoT devices significantly improve operational efficiency. By automating tasks, optimizing processes, and providing real-time feedback, IoT systems streamline workflows and minimize manual intervention. This translates into reduced labor costs, improved productivity, and increased output. Consider a logistics company using IoT sensors to track shipments in real time. This real-time visibility allows for dynamic routing adjustments, reducing delivery times and fuel consumption.

Real-time data analysis also enables cost reduction in various sectors. For instance, energy consumption in buildings can be monitored and optimized using smart sensors. By analyzing energy usage patterns, building managers can identify areas for improvement, implement energy-saving measures, and reduce energy bills. This is a powerful example of how IoT data can directly impact cost savings across different industries.

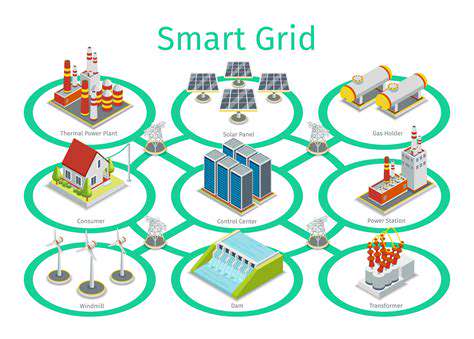

Smart Grid Technologies and Enhanced Grid Management

Smart Grid Technologies: A Revolution in Energy Management

Smart grid technologies represent a paradigm shift in how we generate, transmit, and consume electricity. These innovative systems leverage digital communication and advanced sensors to create a more responsive, efficient, and sustainable energy infrastructure. By integrating these technologies, the energy sector can optimize resource allocation, improve grid stability, and enhance the overall customer experience.

Smart grids are designed to be more resilient to outages and disruptions. This resilience is achieved through real-time monitoring and control capabilities, enabling faster detection and response to potential problems. This proactive approach minimizes downtime and ensures the reliability of power delivery.

Advanced Metering Infrastructure (AMI)

AMI is a cornerstone of smart grids, allowing utilities to collect real-time data on energy consumption from individual customers. This detailed data enables personalized energy management strategies and provides valuable insights into energy usage patterns, facilitating demand response programs and proactive maintenance schedules.

Distribution Automation (DA)

Distribution automation systems automate the control of distribution networks, enabling faster and more efficient responses to grid disturbances and outages. This automation significantly reduces the time required to restore power after disruptions. This efficiency translates into reduced costs and improved customer satisfaction.

Demand Response Programs

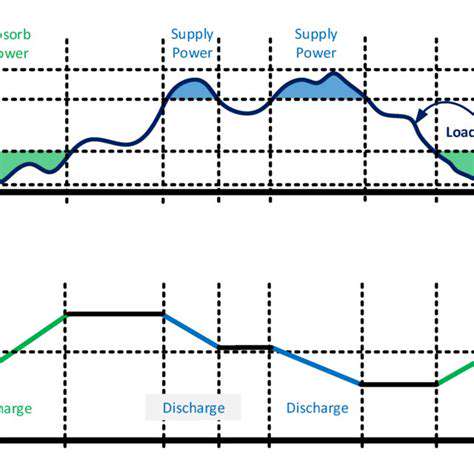

Demand response programs incentivize customers to adjust their energy consumption during peak hours, reducing the strain on the grid. This approach helps to balance supply and demand, leading to reduced reliance on expensive peaking power plants and a more sustainable energy system. By providing feedback and incentives, smart grid technologies can encourage responsible energy use.

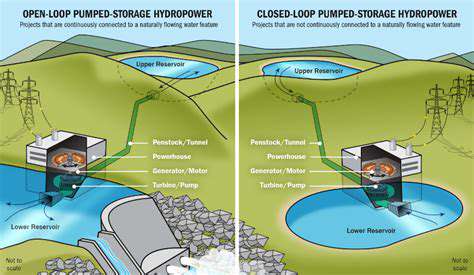

Grid Modernization and Sustainability

Smart grids play a crucial role in modernizing the existing energy infrastructure, making it more efficient and sustainable. This modernization involves the integration of renewable energy sources, such as solar and wind, into the grid. These systems allow for the efficient management of fluctuating renewable energy generation, ensuring a reliable and clean energy supply.

Cybersecurity Considerations

As smart grids become increasingly interconnected, cybersecurity becomes a paramount concern. Protecting critical infrastructure from cyberattacks is essential to maintain the reliability and stability of the grid. Robust cybersecurity protocols and regular security audits are necessary to prevent disruptions and ensure the safety and integrity of the system.

Customer Engagement and Benefits

Smart grid technologies empower customers with more control over their energy consumption. This includes features like real-time energy monitoring, personalized energy reports, and participation in demand response programs. This enhanced engagement fosters a more active role for customers in managing their energy use and reducing their environmental footprint. Smart grids facilitate a more collaborative relationship between utilities and consumers, leading to a more sustainable and efficient energy system.

Enabling Proactive Maintenance and Optimization

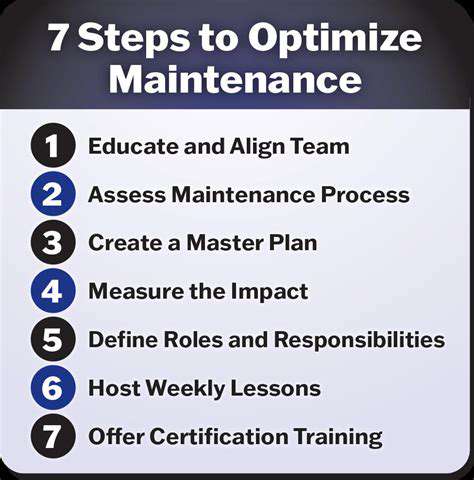

Optimizing Preventive Maintenance Strategies

Preventive maintenance is a crucial aspect of maintaining optimal equipment performance and extending its lifespan. By implementing proactive strategies, businesses can significantly reduce costly breakdowns and downtime. A well-defined preventive maintenance schedule, tailored to the specific needs of each piece of equipment, is vital for success. This involves considering factors such as usage patterns, environmental conditions, and manufacturer recommendations to ensure that maintenance tasks are performed at the appropriate intervals. Proactive maintenance also includes regular inspections and monitoring to identify potential issues before they escalate into major problems.

Regular inspections and monitoring of equipment are key components of a successful proactive maintenance program. This allows for early detection of developing issues, reducing the risk of unexpected breakdowns. Implementing a robust system for tracking maintenance activities and documenting findings is essential to ensure accountability and continuous improvement. Effective communication between maintenance teams and operators is also critical to ensure that everyone is aware of maintenance schedules and procedures, minimizing disruptions to production.

Predictive Maintenance Technologies

Predictive maintenance leverages advanced technologies to anticipate potential equipment failures. This approach involves monitoring equipment performance using sensors and data analytics to identify patterns and anomalies that may indicate impending problems. This data-driven approach allows for more precise maintenance scheduling, reducing unnecessary downtime and saving resources. Predictive maintenance often involves the use of machine learning algorithms to analyze complex data sets and predict future failures with greater accuracy.

Employing predictive maintenance technologies can significantly enhance equipment reliability and reduce maintenance costs. By identifying potential issues before they occur, businesses can avoid costly breakdowns and optimize their maintenance schedules. The increased accuracy of predictive maintenance allows for a more strategic approach to maintenance, maximizing equipment uptime and minimizing operational disruptions. This approach also helps reduce waste and environmental impact by minimizing unnecessary repairs and replacements.

Implementing a Comprehensive Maintenance Program

A comprehensive maintenance program should encompass all aspects of equipment management, from preventative measures to predictive technologies. This integrated approach ensures that all equipment is properly maintained throughout its lifecycle. This includes developing clear maintenance procedures, training personnel on these procedures, and establishing a robust system for tracking and reporting maintenance activities.

Establishing clear maintenance procedures is fundamental to a comprehensive maintenance program. These procedures should be detailed, easily understandable, and consistently followed. Training personnel on these procedures ensures that everyone is knowledgeable about their responsibilities and how to perform maintenance tasks safely and effectively.

Impact on Operational Efficiency

Proactive maintenance strategies directly impact operational efficiency by minimizing downtime and maximizing equipment uptime. This translates into increased production output, reduced costs, and enhanced profitability. By preventing breakdowns and addressing issues early, businesses can avoid significant financial losses associated with unplanned repairs and lost production time.

Improved operational efficiency directly correlates to enhanced profitability. Less downtime means more production time, ultimately increasing revenue and reducing operational costs. The benefits of proactive maintenance extend beyond cost savings to encompass improved safety and environmental performance.

Integration with IoT and Data Analytics

Integrating Internet of Things (IoT) devices and data analytics tools into maintenance programs can significantly enhance the effectiveness of proactive strategies. IoT sensors can collect real-time data on equipment performance, providing valuable insights into potential issues. Data analytics can then be used to identify patterns and anomalies in the data, enabling proactive responses to potential equipment failures.

The integration of IoT and data analytics allows for a more comprehensive understanding of equipment health and performance. This leads to improved maintenance scheduling and reduced downtime. This data-driven approach also enables better resource allocation and optimized maintenance budgets.

Cost Savings and Return on Investment

Implementing proactive maintenance strategies often results in substantial cost savings over time. By preventing breakdowns and reducing downtime, businesses can avoid costly repairs and replacements. The long-term cost savings associated with proactive maintenance often outweigh the initial investment in implementing the strategies. This is especially true when considering the potential for reduced labor costs, material costs, and lost revenue.

A proactive maintenance approach fosters a culture of proactive problem-solving, which ultimately leads to a higher return on investment. The reduced downtime and improved operational efficiency directly contribute to greater profitability and sustainability for businesses.

Enhanced Consumer Engagement and Sustainability

Enhanced Consumer Engagement

The integration of IoT devices into consumer products allows for a more interactive and personalized experience. Consumers can engage directly with the products they use, receiving real-time feedback, customized recommendations, and even participating in the design and improvement processes. This level of engagement fosters a stronger connection between the consumer and the brand, leading to increased loyalty and potentially driving repeat purchases. This direct interaction transcends traditional marketing methods, creating a more dynamic and responsive relationship.

Beyond product interaction, IoT enables personalized experiences beyond the product itself. Think of tailored recommendations for complementary products based on usage patterns, or proactive maintenance alerts designed to extend the lifespan of the product. This proactive approach aligns with consumer preferences for efficiency and convenience, while also reducing unnecessary waste.

Sustainable Practices Enabled by IoT

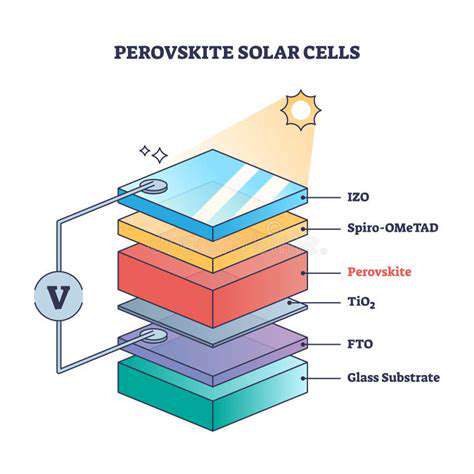

IoT plays a crucial role in optimizing resource utilization and reducing environmental impact throughout the product lifecycle. Sensors embedded in devices can monitor energy consumption, identify inefficiencies, and facilitate adjustments in real-time. This data-driven approach allows for proactive measures to reduce energy waste and optimize production processes. By reducing energy consumption and waste, companies can significantly contribute to a more sustainable future.

Decentralized Supply Chain Visibility

IoT devices deployed throughout the supply chain provide real-time visibility into every stage of production and distribution. This transparency allows for quicker responses to potential disruptions, efficient inventory management, and improved logistics. Consumers can track their products from origin to delivery, fostering trust and confidence in the supply chain process. This improved traceability can also be instrumental in verifying ethical sourcing practices and combating counterfeiting.

Improved Product Maintenance and Lifecycle Management

IoT-enabled devices can monitor the health and performance of products in real-time. This allows for proactive maintenance, preventing unexpected breakdowns and extending the lifespan of products. Predictive maintenance, based on data collected by IoT sensors, can significantly reduce downtime and maintenance costs. Moreover, this data can be used to optimize product design and manufacturing processes, further enhancing the product's sustainability and longevity.

Data-Driven Insights for Optimization

The vast amount of data generated by IoT devices provides valuable insights into consumer behavior, product usage patterns, and operational efficiencies. Analyzing this data allows companies to identify areas for improvement, personalize products and services, and optimize manufacturing processes. This data-driven approach leads to more effective decision-making, improved resource allocation, and ultimately a more sustainable and profitable business model. Furthermore, the data can be used to inform future product development and design.