Vertical Axis Wind Turbines: Urban Solutions

Adaptability and Versatility: Tailoring to Diverse Urban Wind Conditions

Optimizing Vertical A for Variable Wind Profiles

Vertical A's adaptability plays a pivotal role in urban settings, where wind patterns are notoriously unpredictable. Understanding these variations is essential for maintaining structural stability and performance. Engineers must account for fluctuating wind speeds, shifting directions, and localized turbulence common in dense urban areas. Modern design approaches now integrate advanced modeling tools to simulate dynamic wind behaviors, enabling proactive structural adjustments.

Urban landscapes create unique wind challenges. Narrow streets act as wind tunnels, while tall buildings deflect airflow unpredictably. These conditions demand rigorous wind tunnel testing and computational fluid dynamics (CFD) simulations to identify potential stress points. By analyzing these patterns, engineers can reinforce critical structural elements where wind loads are most intense.

Material Selection and Structural Design for Resilience

Choosing the right materials is fundamental for Vertical A structures. Materials must combine lightweight properties with exceptional strength to withstand variable wind loads. Fatigue resistance is particularly crucial as structures endure continuous cyclic loading from wind forces. Modern composites and high-performance alloys often provide the necessary balance between durability and flexibility.

Innovative structural systems dramatically improve wind resilience. Engineers now incorporate adaptive bracing configurations and energy-dissipating dampers. These solutions undergo extensive validation through both digital simulations and physical prototype testing. Such measures effectively reduce vibration-induced stresses, preserving structural integrity throughout the structure's lifespan.

Innovative Design Strategies for Enhanced Wind Performance

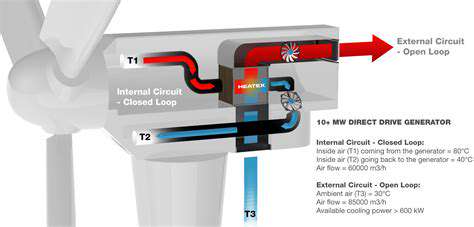

Aerodynamic shaping offers significant benefits for Vertical A structures. Strategic placement of fins and louvers can substantially reduce wind resistance. Some designs feature active aerodynamic control systems that automatically adjust structural components in real-time. This dynamic approach compensates for sudden wind shifts, maintaining stability during extreme conditions.

Smart monitoring systems represent the cutting edge in wind adaptation. Networks of sensors track wind behavior across the structure, feeding data to automated response systems. These systems can trigger adjustments to structural elements within milliseconds, creating a continuous feedback loop that optimizes performance under changing conditions.

Challenges and Future Developments: Enhancing Efficiency and Affordability

Optimizing Vertical Farming Systems

Vertical farming presents unique challenges in system optimization. Precise environmental control requires sophisticated automation and sensor networks. These systems must dynamically adjust lighting, temperature, and nutrient delivery based on real-time plant needs, significantly improving resource efficiency.

The high initial investment remains a major barrier. Creative financing solutions and government incentives could make vertical farming more accessible. Public-private partnerships may prove particularly valuable in sharing the financial burden while combining agricultural and technological expertise.

Addressing the Nutritional Value of Crops

Nutrient optimization in controlled environments is an ongoing research focus. Scientists are developing advanced hydroponic systems that precisely deliver essential minerals. These innovations aim to match or exceed the nutritional quality of traditionally grown produce while maintaining superior consistency.

Post-harvest handling requires equal attention. Novel packaging solutions and optimized cold chain logistics help preserve nutritional content from farm to consumer, enhancing the appeal of vertical farm products.

Innovations in Vertical Farming Technology

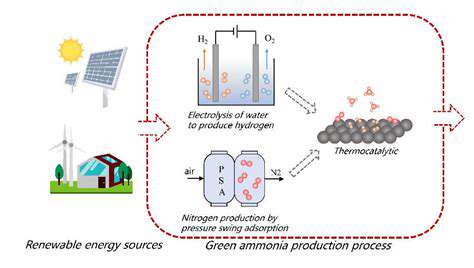

Lighting technology continues to evolve rapidly. Next-generation LED systems now offer customizable spectra tuned to specific crop requirements. When combined with smart sensors, these systems automatically adjust intensity and duration, dramatically reducing energy use while boosting yields.

Artificial intelligence transforms farm management. Machine learning algorithms analyze vast datasets to predict growth patterns and optimize resource allocation. This predictive capability enables proactive adjustments before issues arise, significantly improving operational efficiency.

Economic Viability and Sustainability

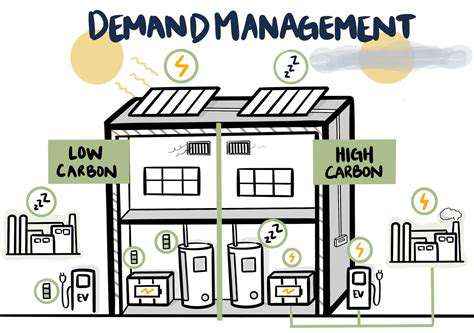

While promising, vertical farming must address cost concerns to achieve mainstream adoption. Energy efficiency improvements and water recycling systems are reducing operational expenses. Some facilities now integrate with urban infrastructure, utilizing waste heat from buildings to offset climate control costs.

Market development remains crucial. Building direct relationships with local retailers and educating consumers about the benefits of vertically farmed produce can drive demand. Emphasizing the year-round availability and reduced environmental impact helps position these products as both sustainable and practical choices.