Compressed Air Energy Storage (CAES): A Unique Solution

Overcoming Challenges and Future Prospects

Overcoming Technological Hurdles

Compressed air energy storage (CAES) technology faces several significant challenges that need to be addressed for widespread adoption. One key hurdle is the high capital cost associated with building and maintaining the large-scale storage facilities required for significant energy storage capacity. This high initial investment can be a deterrent for both private companies and governments looking to deploy CAES on a large scale. Furthermore, the efficiency of the process, while improving, still has room for enhancement to minimize energy losses during compression and expansion cycles. These losses translate directly into reduced overall energy output, impacting the economic viability of CAES systems.

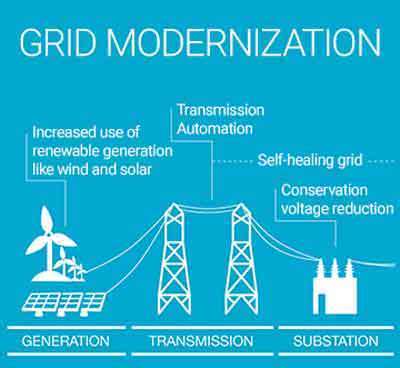

Another critical area of focus is the design and construction of robust and durable storage vessels. These vessels need to withstand the immense pressures generated during the compression process, demanding advanced materials and sophisticated engineering solutions. The safety and reliability of these structures are paramount, as any failure could have serious consequences. Moreover, integration with existing power grids poses challenges, requiring careful consideration of grid infrastructure and control systems to ensure seamless energy transfer and avoid disruptions to the power supply.

Optimizing Efficiency and Cost-Effectiveness

A crucial aspect of advancing CAES technology is the ongoing refinement of compression and expansion techniques. Researchers are actively exploring innovative methods to reduce energy losses during these critical stages of the storage process. For example, advancements in compressor designs and the use of advanced materials could significantly improve efficiency. This optimization would not only enhance the overall energy output but also reduce the operating costs associated with CAES systems.

Cost reduction is another crucial element. Reducing the capital expenditure associated with CAES facilities is essential for wider adoption. This can be achieved through the development of more cost-effective storage vessel designs, utilizing readily available materials, and employing innovative construction techniques. Exploring alternative storage methods such as underground caverns could also potentially lower the cost of large-scale storage infrastructure. Further research into optimizing the entire CAES system from compression to power generation will be crucial for improving cost-effectiveness.

The development of innovative materials and technologies for both compression and expansion processes is essential. These advancements will not only improve the efficiency but also the durability and longevity of the CAES system. Research into materials that can withstand higher pressures and temperatures for longer periods will be critical for enhancing the overall performance and reliability of the technology.

Future Prospects and Market Potential

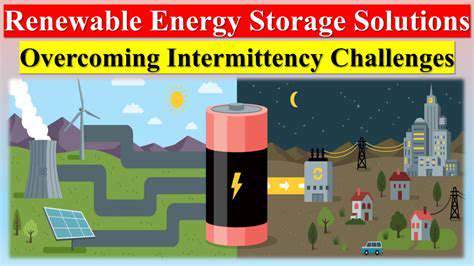

Despite the challenges, the future prospects of CAES look promising. With ongoing research and development, the technology is expected to become more efficient, cost-effective, and safer. This could lead to a significant increase in its adoption for grid stabilization and renewable energy integration. The increasing demand for energy storage solutions, driven by the integration of intermittent renewable energy sources like solar and wind, creates a strong market potential for CAES.

The potential for CAES to play a crucial role in decarbonizing the energy sector is significant. As governments worldwide strive to reduce their carbon footprint, CAES could emerge as a vital tool for storing renewable energy and balancing the intermittent nature of solar and wind power. This development is expected to create new job opportunities in the energy sector and stimulate innovation in related fields, further supporting economic growth.

Applications and the Future of CAES

CAE in Automotive Design

Computer-aided engineering (CAE) is revolutionizing the automotive industry, enabling engineers to design and test vehicles with unprecedented accuracy and efficiency. CAE software allows for the simulation of various aspects of a vehicle's performance, such as structural integrity under stress, aerodynamic efficiency, and thermal management. This iterative process significantly reduces the need for costly and time-consuming physical prototypes, leading to faster development cycles and lower production costs. CAE simulations predict the behavior of components and systems under different operating conditions, enabling engineers to identify potential weaknesses and optimize designs early in the process.

The application of CAE in automotive design extends beyond structural analysis. It also plays a crucial role in optimizing the vehicle's aerodynamic performance, reducing drag, and improving fuel efficiency. Furthermore, CAE tools are used to simulate the thermal behavior of components, ensuring optimal temperature control and preventing overheating issues. This comprehensive approach to design and testing ultimately translates into safer, more efficient, and more environmentally friendly vehicles.

CAE in Aerospace Engineering

CAE plays a vital role in the aerospace industry, where the safety and reliability of aircraft are paramount. CAE simulations are used to analyze the structural integrity of aircraft components under extreme conditions, such as high altitudes and high speeds. By simulating various flight scenarios, engineers can identify potential design flaws and areas for improvement, ensuring the safety and performance of the aircraft.

CAE also contributes significantly to the design and optimization of aircraft engines. The complex interactions between different components, such as the combustion chamber and turbine blades, are meticulously simulated to ensure optimal performance and efficiency. These simulations allow for the identification of potential issues and the optimization of design features, ultimately leading to more powerful and fuel-efficient aircraft engines. This process is critical in reducing costs and improving the overall performance of aerospace systems.

CAE in Mechanical Engineering

In mechanical engineering, CAE software is used to analyze and optimize a wide range of mechanical components and systems. From the design of gears and bearings to the simulation of complex machinery, CAE provides a powerful tool for engineers to virtually test and refine their designs. This approach enhances the overall performance and reliability of the final products. CAE software allows for the accurate modeling of mechanical components, providing detailed insights into their behavior under various conditions.

The ability to virtually test designs using CAE significantly reduces the need for physical prototypes, saving both time and resources. This iterative process facilitates the identification and resolution of potential issues early in the design phase, leading to more efficient and effective designs. CAE simulations are essential for ensuring that mechanical systems meet performance specifications and safety standards.

CAE in Biomedical Engineering

The application of CAE extends beyond traditional engineering disciplines, including the field of biomedical engineering. CAE software is used to design and analyze medical implants, prosthetics, and other medical devices. CAE simulations allow engineers to evaluate the performance and functionality of these devices under various physiological conditions. This precise approach to design ensures that the devices are safe and effective for their intended use. By simulating the interaction of the device with the human body, engineers can identify potential issues and optimize the design.

CAE can also be used to simulate the behavior of tissues and organs, enabling the development of new treatments and therapies. This simulation-based approach offers significant potential for improving patient outcomes and advancing medical technology. The applications of CAE in biomedical engineering are continually expanding, offering innovative solutions to complex healthcare challenges.