The Role of Digitalization and AI in Renewable Energy Systems

Industrial operations are undergoing a transformation with the adoption of predictive maintenance, which replaces traditional reactive approaches. Rather than responding to equipment failures after they occur, this method focuses on identifying early warning signs to perform maintenance before problems escalate. This shift not only cuts downtime dramatically but also boosts operational efficiency, resulting in lower costs and higher profits.

Advanced technologies and data analytics enable industries to fine-tune maintenance schedules, avoiding unnecessary repairs and extending equipment life. The key idea is to detect subtle signs of potential failure, allowing for timely interventions that prevent expensive breakdowns and safety risks.

Data Collection and Analysis: The Foundation of Predictive Maintenance

Effective predictive maintenance depends on gathering and analyzing extensive data from multiple sources, including sensor readings, operational metrics, and past maintenance records. Reliable data collection is essential for creating accurate predictive models and ensuring the success of maintenance strategies.

Sophisticated algorithms and machine learning techniques process this data to uncover patterns and anomalies that may indicate future equipment failures. This analysis helps predict failure risks and determine the best times for maintenance.

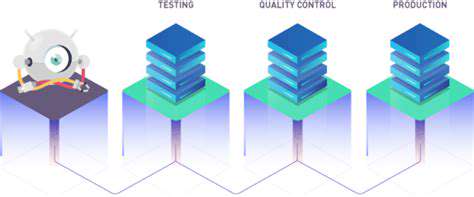

Advanced Technologies Empowering Predictive Maintenance

Cutting-edge technologies like sensors, the Internet of Things (IoT), and cloud computing play a pivotal role in implementing predictive maintenance. They enable continuous monitoring of equipment performance and the collection of comprehensive datasets.

Sensors installed in machinery track critical parameters such as temperature, vibration, and pressure in real time. This data, combined with advanced analytics, helps identify potential issues before they become serious problems.

Improved Operational Efficiency and Reduced Costs

Predictive maintenance significantly boosts operational efficiency by reducing downtime and maximizing equipment availability. By preventing unexpected outages, it ensures smoother production schedules and higher productivity.

Cost savings come from multiple sources, including lower repair expenses, reduced inventory needs, and minimized production losses. These factors directly improve profitability and return on investment.

Enhanced Safety and Reduced Risk

Beyond financial benefits, predictive maintenance enhances workplace safety by spotting potential hazards early. Detecting equipment malfunctions before they escalate helps prevent serious accidents, protecting workers and property.

Proactively addressing risks ensures a safer work environment, which is a critical component of any predictive maintenance program.

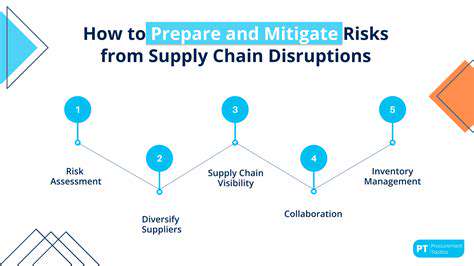

Maintenance Optimization and Scheduling

Predictive maintenance allows for smarter scheduling, ensuring maintenance happens during low-impact periods. This minimizes disruptions and keeps production running smoothly.

By analyzing data trends and predicting failures, organizations can plan maintenance in advance, reducing downtime and improving efficiency.

Future Trends and Innovations

The future of predictive maintenance is bright, with ongoing advancements in technology and analytics. Artificial intelligence (AI) and machine learning (ML) will enhance the precision and speed of predictive models, enabling even better failure forecasts.

New sensor technologies and real-time data processing will further refine predictive maintenance, offering greater efficiency and cost savings for industries.

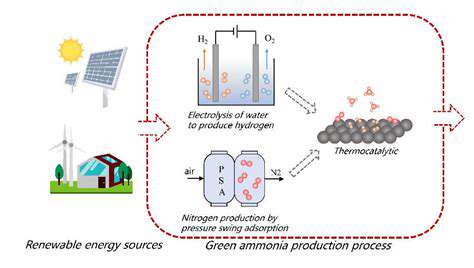

Optimizing Energy Storage and Distribution

Optimizing Energy Storage Systems

Energy storage systems are vital for integrating renewable energy into the grid. Efficient energy storage technologies can greatly enhance grid stability and reliability, supporting the shift to sustainable energy. These systems help manage the variability of renewable sources like solar and wind power.

Various technologies, including advanced batteries, pumped hydro storage, and compressed air energy storage, are being developed to improve energy storage. Each has unique benefits and challenges in terms of cost, efficiency, and scalability, making it important to choose the right solution for specific needs.

Advanced Battery Technologies

Advanced battery technologies are key to improving energy storage capacity and efficiency. Research focuses on developing new chemistries that store more energy, last longer, and are safer. These innovations could reduce costs and environmental impact.

Solid-state batteries are particularly promising, offering higher energy density and better safety than traditional lithium-ion batteries. However, scaling up production and cutting costs remain challenges.

Pumped Hydro Storage

Pumped hydro storage, a well-established technology, provides large-scale energy storage by using elevated reservoirs to generate electricity. It offers high capacity and efficiency, making it ideal for grid applications.

While highly efficient and long-lasting, pumped hydro requires significant investment and suitable geography, limiting its deployment in some areas.

Compressed Air Energy Storage

Compressed air energy storage (CAES) stores energy by compressing air, which can later generate electricity. It can be integrated into existing power plants for large-scale storage.

CAES is effective for long-term storage but faces challenges with high-pressure operation and safety concerns.

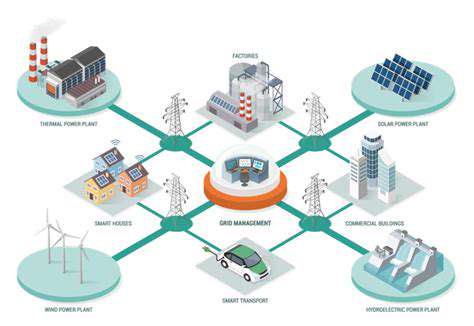

Grid Integration and Management

Integrating energy storage into grids requires smart management strategies. Smart grids with advanced control systems are essential for balancing energy flow and meeting demand fluctuations, ensuring stability and reliability.

Real-time monitoring and control, powered by advanced algorithms, optimize energy dispatch and reduce losses, creating a more sustainable system.

Economic and Environmental Considerations

The economic viability of energy storage is crucial for widespread adoption. Government incentives can drive investment in these technologies. Assessing environmental impacts, from production to disposal, is also key to choosing sustainable solutions.

Reducing costs through innovation in materials and manufacturing will make energy storage more competitive, enabling broader use.

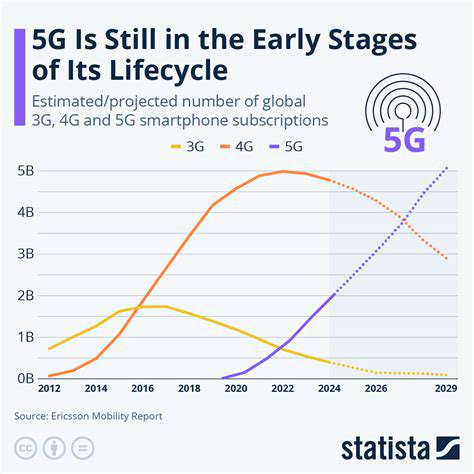

The Future of Renewable Energy: A Digitalized Landscape

Data-Driven Insights for Optimization

The digital revolution is transforming renewable energy, enabling unprecedented efficiency. Real-time data from weather, grid performance, and consumption allows for dynamic adjustments in energy generation and distribution. This approach minimizes waste and maximizes resource use.

Imagine solar panels adjusting output based on sunlight or wind turbines optimizing blade angles for wind speed. Digital platforms powering these algorithms will create a more responsive and sustainable energy system.

Smart Grid Technologies for Enhanced Reliability

Digitalization is key to smart grids, which enable two-way communication between suppliers and consumers. This allows real-time monitoring of energy flow, reducing outages and improving maintenance.

Smart meters give consumers control over their energy use, leading to lower bills and greener habits. This also supports smoother integration of renewable sources.

Decentralized Energy Systems and Microgrids

Digital tools are enabling decentralized energy systems, where renewables are spread across communities. This increases resilience, as the failure of one source doesn’t disrupt the whole system. Microgrids provide localized solutions and greater energy independence.

Digital platforms coordinate these distributed sources, optimizing energy flow and enhancing efficiency, especially in remote or emergency scenarios.

Advanced Modeling and Forecasting for Enhanced Planning

Digital tools and models simulate scenarios like weather patterns and energy demand to forecast needs and optimize resource allocation. This helps utilities and policymakers plan infrastructure investments and develop effective renewable energy policies.

The Role of Artificial Intelligence in Renewable Energy

AI is set to revolutionize renewable energy by optimizing storage, predicting maintenance needs, and identifying new opportunities. AI analyzes vast datasets to spot trends, enabling proactive decisions that cut costs and improve reliability.

This technology will drive more efficient use of renewable infrastructure and spur further investment in sustainable energy.