Cybersecurity Challenges in Renewable Energy Grid Systems

Global supply chains are intricate networks of interconnected businesses, spanning continents and relying on a multitude of factors for smooth operation. Disruptions in any part of this complex system can have cascading effects, impacting everything from consumer goods availability to manufacturing output. These disruptions can be triggered by various unforeseen events, including natural disasters, geopolitical instability, pandemics, and even labor shortages.

The interconnectedness of modern supply chains makes them particularly vulnerable. A single factory closure in one region can create ripple effects throughout the entire network, leading to delays, shortages, and increased costs for businesses and consumers alike. Understanding the root causes of these disruptions is crucial for developing effective mitigation strategies.

Geopolitical Instability and Trade Wars

Geopolitical tensions and trade wars can significantly disrupt supply chains. Tariffs, sanctions, and political instability in key regions can create barriers to trade, leading to delays in shipments, increased costs, and shortages of essential goods. The unpredictable nature of these events makes it challenging for businesses to plan and adapt to the changing landscape.

Trade agreements and diplomatic relations directly impact the flow of goods and materials. Changes in these areas often lead to unexpected disruptions and require companies to adjust their logistics and sourcing strategies to maintain operations.

Natural Disasters and Climate Change

Natural disasters, such as earthquakes, floods, hurricanes, and wildfires, can severely disrupt supply chains. These events often damage infrastructure, disrupt transportation networks, and lead to production halts. The frequency and intensity of these events are increasing due to climate change, further exacerbating the challenges faced by businesses.

Climate change-related disruptions, like extreme weather patterns, can significantly impact agricultural production and raw material availability, affecting the supply of essential goods. Businesses need to incorporate climate change factors into their risk assessments and strategies to build resilience.

Logistics Bottlenecks and Infrastructure Limitations

Bottlenecks in transportation and logistics networks can lead to significant delays and inefficiencies in supply chains. Congestion at ports, limited warehousing capacity, and inadequate infrastructure can all contribute to disruptions. These issues are often exacerbated by the increasing volume of global trade and the need for faster delivery times.

Modern supply chains rely heavily on efficient logistics. Improving infrastructure, optimizing transportation routes, and enhancing warehousing capacity are critical to mitigating logistics bottlenecks and enhancing supply chain resilience.

Labor Shortages and Skills Gaps

Labor shortages and skills gaps in key sectors can create significant disruptions in supply chains. A lack of qualified workers in manufacturing, transportation, and logistics can lead to production delays, quality issues, and increased costs. These shortages can be particularly acute in specific industries, such as trucking, and can have widespread consequences.

Investing in training programs, attracting skilled labor, and exploring automation solutions are essential to address labor shortages and skills gaps to ensure long-term supply chain stability.

Pandemic-Related Disruptions

The COVID-19 pandemic highlighted the vulnerability of global supply chains to unforeseen events. Lockdowns, travel restrictions, and disruptions in manufacturing and transportation significantly impacted the availability of goods and services. The pandemic underscored the need for greater resilience and flexibility in supply chain management.

Supply chain diversification, building inventory buffers, and improving communication and collaboration between stakeholders are crucial strategies to minimize the impact of future pandemics.

Technological Advancements and Their Impact

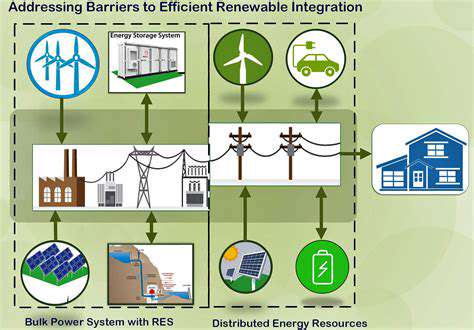

Technological advancements, while potentially improving efficiency, can also introduce new vulnerabilities in supply chains. Dependence on sophisticated technologies can make supply chains more vulnerable to cyberattacks and disruptions in the digital infrastructure. Implementing robust cybersecurity measures and ensuring data security are crucial for mitigating these risks.

The integration of technology in supply chain management offers opportunities to enhance visibility, optimize processes, and improve decision-making. However, businesses must be mindful of the potential vulnerabilities and take proactive measures to mitigate them.