Hybrid Projects: Offshore Wind and Hydrogen

Electrolysis Fundamentals

Electrolysis, a process that uses an electric current to drive a non-spontaneous chemical reaction, is the cornerstone of hydrogen production. This method involves passing an electric current through an electrolyte, typically an aqueous solution of salts or acids, causing water molecules to split into hydrogen and oxygen. Understanding the fundamental principles of electrolysis is crucial for optimizing the process and maximizing hydrogen yield in a controlled environment.

The efficiency of electrolysis depends heavily on the electrolyte's properties and the electrode materials used. Different electrolytes have varying conductivities and reaction kinetics, impacting the energy required for the process. Choosing appropriate electrode materials is also vital as they influence the reaction rate and potential for corrosion, ultimately affecting the overall system performance. Careful selection of these components is critical for sustainable hydrogen production.

Types of Electrolysis Cells

Several types of electrolysis cells are employed, each with its own advantages and disadvantages. Alkaline electrolysis, for instance, is a mature technology with a relatively low cost. However, its efficiency is somewhat lower compared to other methods. Proton exchange membrane (PEM) electrolysis, on the other hand, offers higher efficiency and faster reaction rates, making it suitable for applications requiring rapid hydrogen production.

Solid oxide electrolysis cells (SOECs) are another category, known for their high operating temperatures. While this high temperature can lead to challenges in terms of materials and system design, SOECs have the potential for high efficiency and operation on various feedstocks. Each technology presents a unique trade-off between cost, efficiency, and scalability, influencing the selection process for specific applications.

Catalyst Materials and Their Role

Catalyst materials play a pivotal role in accelerating the electrochemical reactions within the electrolysis cell. Noble metals like platinum and iridium are frequently used due to their high catalytic activity. However, their scarcity and high cost are significant drawbacks. Researchers are actively exploring alternative, more abundant, and cost-effective catalyst materials to enhance the economic viability of hydrogen production.

Developing robust and durable catalysts is essential for long-term performance and cost-effectiveness. The catalytic activity, stability, and durability of materials significantly impact the overall efficiency and sustainability of the electrolysis process. Further research and development in this area are crucial for the widespread adoption of electrolysis.

Energy Efficiency and Optimization Strategies

Energy efficiency is a critical aspect of hydrogen production through electrolysis. Optimizing the process involves reducing energy consumption while maintaining high hydrogen purity and yield. This optimization process often incorporates strategies such as advanced control systems, improved electrode designs, and the use of renewable energy sources.

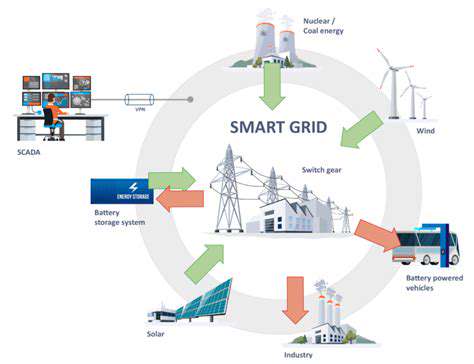

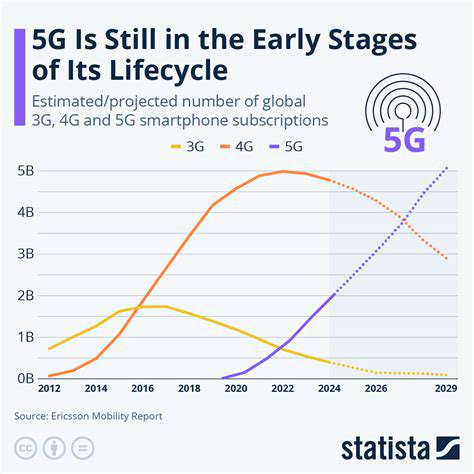

Minimizing energy losses throughout the electrolysis process is paramount. Reducing parasitic losses, such as resistive losses in the electrical components, and optimizing the system configuration contribute to significant efficiency improvements. Furthermore, using renewable energy sources, such as solar or wind power, to power the electrolysis process is a crucial step towards sustainable hydrogen production.

Scaling Up Electrolysis for Industrial Applications

Scaling up electrolysis technology for industrial-scale hydrogen production requires careful consideration of various factors. The process needs to be robust and reliable enough to meet the demands of large-scale applications. Addressing challenges related to infrastructure, materials, and cost is crucial for widespread implementation.

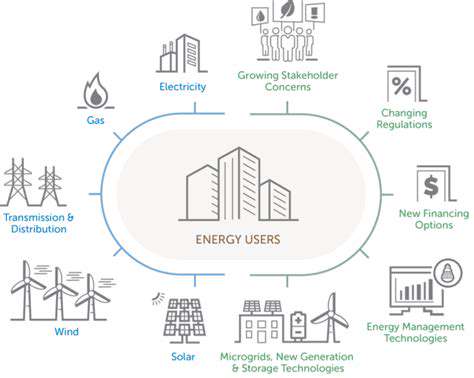

Integrating electrolysis into existing industrial infrastructures presents challenges. Ensuring compatibility with existing power grids and developing efficient transportation and storage solutions for hydrogen are crucial steps in the process. Developing standardized procedures and guidelines is essential for the successful implementation of this technology on a large scale.

Environmental Impact and Sustainability

Hydrogen production through electrolysis, when powered by renewable energy sources, can contribute significantly to a cleaner energy future. The process offers a pathway to decarbonize various sectors, reducing reliance on fossil fuels. The environmental impact, however, also depends on the energy source used to power the electrolysis process.

Minimizing the environmental footprint of hydrogen production is paramount. Choosing renewable energy sources for electrolysis is crucial to avoid greenhouse gas emissions. The overall sustainability of the process relies on the responsible sourcing and utilization of energy, ensuring minimal environmental impact.

Economic Viability and Cost Considerations

The economic viability of hydrogen production through electrolysis is a key factor in its widespread adoption. Reducing the cost of electrolyzers, improving energy efficiency, and increasing the availability of renewable energy sources are essential steps in making the technology economically attractive.

The cost of hydrogen produced via electrolysis needs to be competitive with other hydrogen production methods. Further research, development, and innovation will play a key role in lowering the cost of electrolysis and making it a viable alternative to conventional hydrogen production.

Streamlining production processes is crucial for maximizing output and minimizing waste. Careful analysis of each step, from raw material acquisition to final product delivery, is essential. Identifying bottlenecks and inefficiencies allows for targeted improvements, leading to significant cost savings and increased productivity. This involves evaluating current procedures, examining resource allocation, and considering alternative methods to enhance overall workflow efficiency.