Navigating Regulatory Changes in Corporate Renewable Procurement

Impact on Supply Chain Management and Sourcing Strategies

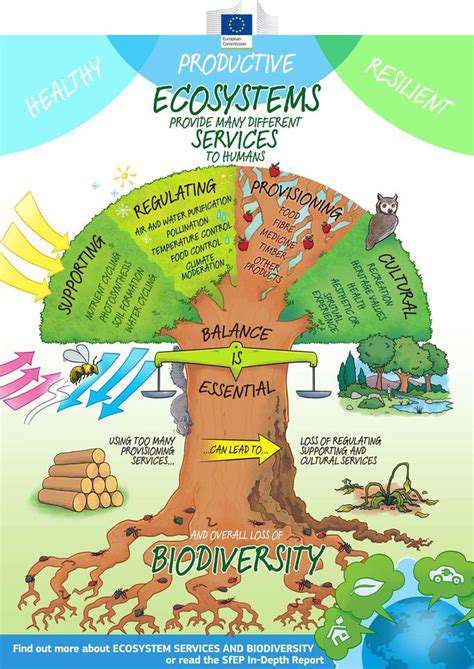

Enhanced Visibility and Traceability

Modern tracking systems revolutionize supply chain transparency, offering real-time monitoring from source to consumer. Businesses now leverage precise location data to anticipate bottlenecks days before they occur, maintaining fluid operations even during peak seasons. The marriage of IoT sensors with advanced analytics has birthed an era of unprecedented operational clarity, turning what was once logistical guesswork into precise, actionable intelligence.

Inventory accuracy has transformed from an aspirational goal to a measurable benchmark. Where spreadsheets once offered hazy snapshots, cloud-based dashboards now provide minute-by-minute updates across global networks. This evolution in tracking technology hasn't just reduced errors—it's redefined how warehouses allocate space and schedule labor.

Optimized Inventory Management

Contemporary inventory systems employ machine learning to predict seasonal fluctuations with startling precision. A footwear manufacturer might adjust stock levels by analyzing weather patterns, social media trends, and local economic indicators simultaneously. These intelligent systems don't just react to demand—they anticipate it weeks in advance, automatically adjusting purchase orders before human managers spot the trend.

The automation of replenishment triggers has eliminated the panic of stockouts. When a popular item's inventory dips below threshold, the system initiates restocking while simultaneously notifying marketing teams to prepare demand-generation campaigns. This symbiotic relationship between inventory control and sales strategy represents supply chain management's new frontier.

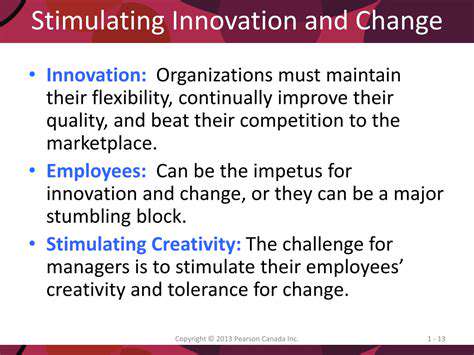

Improved Communication and Collaboration

Cloud-based collaboration platforms have dismantled traditional communication barriers between suppliers, manufacturers, and retailers. A produce distributor in Chile now coordinates directly with a supermarket chain in Canada through shared digital workspaces, resolving quality issues in hours rather than days. This real-time synchronization has compressed decision cycles from weeks to minutes, creating supply networks that respond to disruptions with vaccine-like precision.

The rise of blockchain-enabled documentation has further streamlined cross-border transactions. Shipping manifests, customs forms, and quality certifications now flow through secure, immutable digital ledgers—eliminating paperwork delays that once added weeks to international shipments.

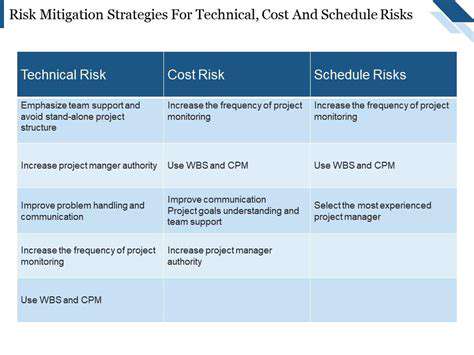

Predictive Analytics and Risk Management

Advanced algorithms now digest geopolitical news, weather satellite data, and port congestion reports to forecast supply chain disruptions before they materialize. A toy company might reroute shipments from Long Beach to Tacoma two weeks before a potential dockworker strike, thanks to predictive models analyzing union negotiation trends. This prescient approach to logistics has turned risk management from reactive firefighting into strategic foresight.

Increased Efficiency and Productivity

Warehouse robotics has evolved beyond simple picking machines to fully autonomous systems that reorganize storage layouts based on real-time demand patterns. These self-optimizing facilities achieve productivity gains that dwarf traditional operations, with some distribution centers reporting 300% increases in order fulfillment rates. The integration of computer vision with robotic arms has virtually eliminated mispicks while accelerating processing speeds beyond human capabilities.

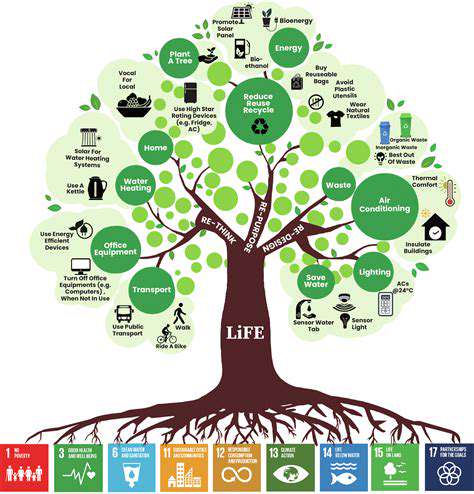

Sustainable Practices and Environmental Impact

Route optimization algorithms now consider real-time traffic, weather conditions, and even road grades to minimize fuel consumption. A beverage company reduced its carbon footprint by 18% simply by having trucks avoid uphill routes when carrying full loads. This new generation of eco-conscious logistics doesn't just benefit the environment—it boosts bottom lines through measurable fuel savings.

Packaging innovations driven by material science algorithms have enabled remarkable waste reduction. One electronics manufacturer slashed shipping volume by 40% through AI-designed packaging that protects delicate components while using 60% less material—a win for both sustainability and shipping costs.

Enhanced Customer Satisfaction

The ripple effects of optimized supply chains manifest most visibly in customer experiences. Where next-day delivery was once a premium service, it's now table stakes for e-commerce players. This delivery revolution has rewritten customer expectations, with 78% of consumers now abandoning carts if same-day shipping isn't offered (Retail TouchPoints, 2023). The brands thriving in this new environment are those whose supply chain agility matches their marketing promises.

Quality assurance has similarly transformed through supply chain integration. Real-time sensor data from shipped products allows companies to proactively address potential defects before customers even notice issues—a preventive approach that's reduced returns by up to 35% in some retail segments.