The Future of Offshore Wind Manufacturing

Optimizing Global Supply Chains

Modern manufacturing ecosystems require sophisticated supply chain optimization strategies. This paradigm shift involves transitioning from isolated, compartmentalized models to integrated network approaches that encompass the complete product lifecycle - from raw material procurement to final distribution. Effective implementation requires instantaneous data exchange, predictive modeling capabilities, and robust communication infrastructure linking all participants, including production facilities, material providers, and logistics partners. Seamless coordination among these diverse entities is essential for reducing delays, maximizing productivity, and mitigating risks associated with international supply chain interruptions.

A fundamental aspect of this optimization process involves creating robust supply networks. Achieving this requires implementing diversified sourcing approaches, building redundancy into transportation systems, and developing adaptable production capacities. By anticipating potential disruptions like political instability or environmental catastrophes, manufacturers can make proactive adjustments to maintain operations and satisfy customer requirements.

The Rise of Regional Manufacturing Hubs

Global manufacturing is experiencing a transition toward regional production centers. Multiple factors drive this trend, including workforce expenses, material availability, and governmental policies. These localized manufacturing clusters offer substantial benefits such as lower transportation costs, quicker delivery schedules, and improved responsiveness to local market conditions. Additionally, regional hubs can stimulate economic development and employment opportunities within specific areas.

However, the growth of regional centers requires careful management of inter-hub relationships. Implementing effective networking strategies that connect these centers through optimized logistics and communication systems is vital for maintaining global supply chain efficiency and robustness.

The specialization of particular manufacturing capabilities within regional hubs can create competitive differentiation, potentially leading to industry-specific innovations. For instance, a region concentrating on electronics production might develop groundbreaking technologies that attract additional sector investment.

When properly coordinated, this localization trend can promote a more balanced and environmentally conscious global economic framework.

Technological Advancements in Manufacturing Networks

Cutting-edge technologies are reshaping manufacturing operations and supply chain interactions. Automated systems, robotic solutions, and artificial intelligence are modernizing production workflows, boosting efficiency, and reducing expenses. These technological tools enable continuous monitoring and adjustment of manufacturing processes, permitting proactive optimization and waste reduction. Additionally, sophisticated analytics provide valuable supply chain performance insights, supporting predictive analysis and proactive risk mitigation.

The incorporation of digital platforms and tools facilitates smooth information sharing and cooperation among stakeholders, increasing transparency and trust across the network. This interconnected strategy enables faster adaptation to market fluctuations and disruptions, ensuring manufacturers can evolve and remain competitive in today's global marketplace. These technological solutions represent critical components for the future of manufacturing and international supply chains.

Supply Chain Resilience and Sustainability in Offshore Wind Manufacturing

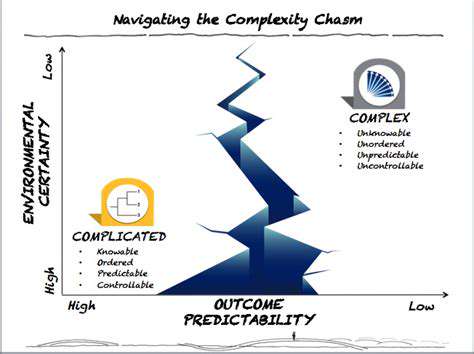

Supply Chain Resilience: A Critical Factor

Supply chain resilience has become an essential consideration in contemporary commerce. Businesses increasingly recognize its importance for risk management and operational continuity. Disruptions stemming from environmental disasters, political conflicts, or health crises can severely impact company operations and financial performance. Resilient supply networks can adapt to and recover from such events rapidly, minimizing operational interruptions and maintaining consistent product availability.

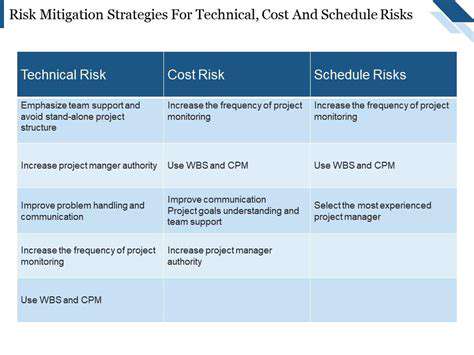

Developing a resilient supply chain demands a comprehensive strategy. This involves detailed analysis of potential supply chain vulnerabilities and creation of contingency measures to address them. Establishing multiple supplier sources and geographically distributed operations helps eliminate single points of failure. Implementing reliable communication systems and information sharing protocols throughout the supply network is crucial for effective risk management and timely response to potential disruptions.

Sustainability: Environmental and Social Considerations

Sustainability has evolved from a peripheral concern to a core business imperative. Incorporating sustainable practices throughout supply chains is vital for enduring success and positive community impact. Organizations now understand that environmental and social factors directly affect supply chain stability. Ecological issues like resource scarcity and environmental contamination can disrupt operations and harm corporate reputations. Proactively addressing these challenges through sustainable supply chain practices is essential for building a more responsible and resilient business ecosystem.

Social responsibility represents another critical dimension. This encompasses ethical employment practices, responsible sourcing, and worker welfare throughout the supply network. Companies should collaborate closely with suppliers to ensure compliance with ethical standards and promote positive social outcomes. This commitment to social responsibility not only strengthens corporate reputation but also cultivates lasting partnerships with suppliers and stakeholders.

Integrating Resilience and Sustainability

The convergence of supply chain resilience and sustainability has become mandatory for businesses pursuing long-term viability. A resilient supply network can better withstand disruptions, while sustainable practices reduce environmental and social risks. When combined, these principles create a reinforcing cycle where sustainability enhances resilience and vice versa. This integrated approach generates enduring value, improves brand perception, and contributes to a more responsible economic future.

Organizations that effectively merge resilience and sustainability into their supply chains gain competitive advantages in adapting to market changes, managing risks efficiently, and building more robust enterprises. Achieving this requires a comprehensive perspective that evaluates both immediate and long-term consequences of business decisions, along with dedication to continuous supply chain improvement.