The Role of AI in Optimizing Energy Storage Dispatch and Lifecycle

Predictive Maintenance with AI

AI-powered predictive maintenance systems analyze vast amounts of data from various sources, including sensor readings, operational logs, and historical maintenance records. This analysis identifies patterns and anomalies that indicate potential equipment failures before they occur. By proactively identifying these issues, organizations can schedule maintenance tasks in advance, minimizing downtime and maximizing equipment lifespan. This approach translates into significant cost savings and improved operational efficiency, especially in industries with complex machinery and high operational costs.

These systems learn from the data to build models that predict the remaining useful life (RUL) of equipment components. This allows for more targeted maintenance, avoiding unnecessary replacements and optimizing resource allocation. The ability to predict when maintenance is needed is a critical aspect of proactive maintenance strategies that AI excels at.

Degradation Modeling and Root Cause Analysis

AI algorithms can model equipment degradation by identifying trends in performance metrics over time. This allows for a deeper understanding of how equipment degrades under various operating conditions. This degradation modeling is crucial for identifying the root causes of equipment failures and implementing preventative measures. This analysis is vital for optimizing maintenance schedules and preventing costly breakdowns.

Identifying the root cause of equipment failure is critical for preventing future occurrences. AI algorithms analyze data to pinpoint specific factors contributing to degradation, whether it's environmental factors, operational errors, or material defects. This data-driven approach leads to more effective maintenance strategies and reduces the likelihood of repeated failures.

Proactive Maintenance Strategies

Implementing proactive maintenance strategies through AI-powered systems enables organizations to schedule maintenance tasks based on predicted failures, rather than reacting to breakdowns. This approach minimizes downtime and reduces the risk of catastrophic failures. This proactive approach is critical for maintaining high operational efficiency and minimizing the cost of unplanned downtime.

Proactive maintenance scheduling is a direct result of AI's ability to predict failures. This means maintenance teams can focus on preventative measures, improving equipment reliability, and extending the lifespan of assets. This shift from reactive to proactive maintenance significantly impacts the bottom line by reducing unexpected expenses and improving overall operational efficiency.

Data Collection and Integration

Effective AI-driven lifecycle management requires robust data collection and integration across various systems. This involves gathering data from sensors, operational logs, maintenance records, and other relevant sources. The integration of this data into a centralized system is crucial for providing comprehensive insights and enabling accurate predictive modeling. Without effective data collection and integration, the AI model cannot function effectively.

Ensuring data quality and consistency is essential for the accuracy of AI models. This includes standardizing data formats, handling missing values, and removing inconsistencies. Data integrity is vital for building reliable predictive models and ensuring the success of proactive maintenance strategies.

AI-Driven Optimization and Cost Reduction

AI-powered lifecycle management tools can optimize maintenance schedules, leading to significant cost reductions. By predicting equipment failures, organizations can avoid costly unplanned downtime and unnecessary replacements. This approach minimizes the need for emergency repairs and ensures optimal resource allocation. This translates directly into cost savings in the long run.

Beyond cost reduction, AI-driven optimization improves overall equipment effectiveness (OEE). By minimizing downtime and maximizing operational efficiency, AI systems enhance the overall productivity of the organization. This increased efficiency translates into higher profits and a more competitive advantage in the market.

The Future of AI in Energy Storage: Integration and Scalability

AI-Powered Predictive Maintenance

Artificial intelligence (AI) is poised to revolutionize energy storage systems by enabling predictive maintenance. By analyzing vast amounts of data from sensors embedded within batteries and storage units, AI algorithms can identify subtle patterns indicative of impending failures. This proactive approach allows for timely intervention, preventing costly downtime and extending the lifespan of these critical components.

Predictive maintenance using AI can significantly reduce maintenance costs and enhance system reliability. This, in turn, translates to substantial savings for energy providers and ultimately, consumers.

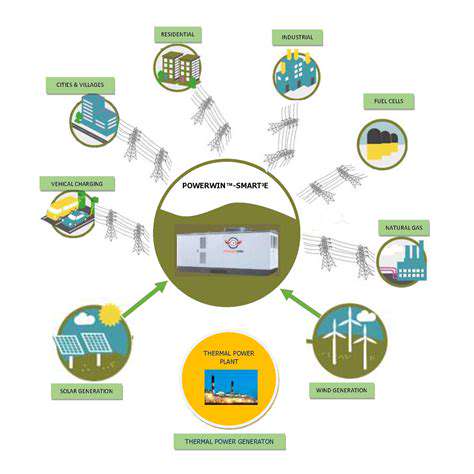

Optimizing Energy Storage Efficiency

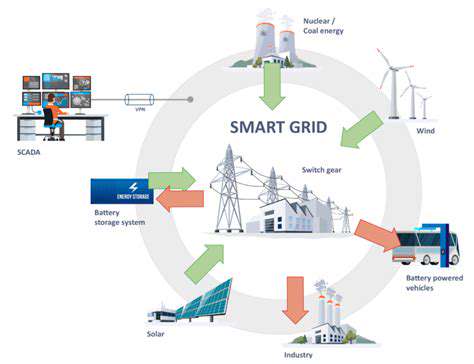

AI algorithms can analyze real-time data from the grid, weather patterns, and energy consumption trends to optimize energy storage systems' performance. This dynamic optimization adjusts charging and discharging schedules to maximize efficiency and minimize energy waste, leading to a more sustainable and cost-effective energy management strategy.

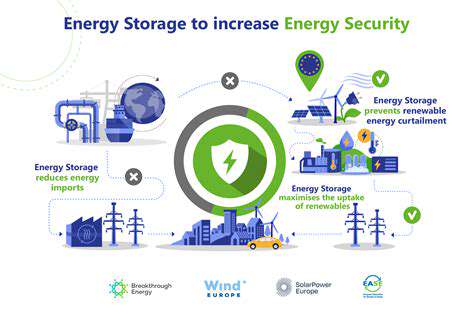

By dynamically adjusting charging and discharging cycles, AI can help ensure that energy is stored and retrieved optimally, reducing losses and improving overall system performance. This is particularly crucial in managing renewable energy sources like solar and wind, which experience intermittent power generation.

Enhanced Battery Management Systems

AI-driven battery management systems can monitor battery health in real-time, identifying potential issues like cell degradation or imbalances. This allows for proactive intervention, preventing battery failures and extending their useful lifespan. This is a critical aspect of improving the longevity and reliability of energy storage solutions.

Early detection of these issues is crucial, as it allows for preventive measures to be taken, reducing downtime and maximizing the overall efficiency of the battery system. This also contributes to reducing the environmental impact by extending the life of these critical components.

Improving Grid Stability and Reliability

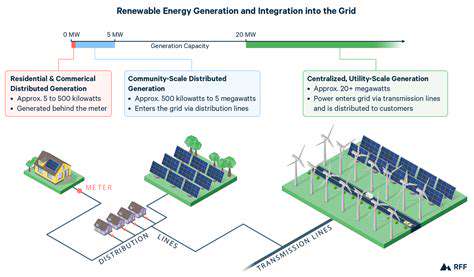

AI can play a vital role in enhancing grid stability by dynamically adjusting energy flow and optimizing the integration of renewable energy sources into the power grid. This sophisticated control enables the grid to respond more effectively to fluctuations in supply and demand, improving overall reliability and reducing the risk of blackouts.

Developing Novel Energy Storage Technologies

AI can accelerate the development of new and innovative energy storage technologies by identifying promising research avenues and optimizing material compositions. By simulating various scenarios and analyzing experimental data, AI can help researchers pinpoint the most promising avenues for development.

This accelerates the pace of innovation and potentially leads to more efficient, cost-effective, and environmentally friendly energy storage solutions for the future. This is especially important as the demand for reliable and affordable energy storage continues to grow.

AI-Driven Forecasting for Energy Demand

AI algorithms can analyze historical and real-time data to predict energy demand with greater accuracy. This predictive capability allows energy storage systems to anticipate fluctuations in demand, enabling more efficient energy management and reducing waste. This predictive capability also helps in optimizing the use of renewable energy sources.

Accurate forecasting of energy demand is vital for optimizing energy storage deployment and reducing the need for expensive peak-demand power plants. AI's ability to refine these predictions can be a game-changer in the energy sector.