The Role of AI in Offshore Wind Operations

Predictive Maintenance for Enhanced Turbine Lifespan

Predictive Maintenance Strategies

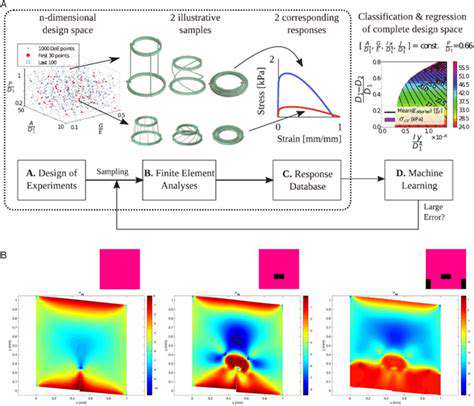

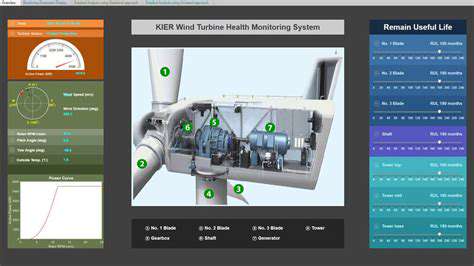

Predictive maintenance (PdM) utilizes data analytics and machine learning to anticipate equipment failures before they occur. This proactive approach contrasts with reactive maintenance, which addresses failures after they happen. By identifying patterns and anomalies in sensor data, PdM systems can predict potential issues, allowing for timely maintenance interventions and minimizing downtime. This proactive approach significantly reduces operational costs associated with unexpected equipment breakdowns.

Different PdM strategies employ various techniques, including vibration analysis, thermal imaging, and acoustic monitoring. These methods capture data from equipment and feed it into algorithms that identify trends and anomalies. Machine learning algorithms excel in recognizing these subtle patterns, enabling early detection of potential failures. These early warnings empower maintenance teams to schedule preventative maintenance tasks, thereby avoiding costly breakdowns and preserving equipment lifespan.

Data Collection and Analysis

A crucial aspect of effective PdM is the robust collection and analysis of equipment data. Sensors strategically placed on machinery capture real-time data on parameters like vibration, temperature, and pressure. This data is then fed into sophisticated analytics platforms. These platforms use advanced algorithms to identify anomalies in the collected data that could signal potential failures.

The quality and quantity of data are paramount. Comprehensive data sets provide more reliable insights and improve the accuracy of predictive models. Real-time data streams are especially valuable for identifying emerging problems quickly, enabling swift intervention and minimizing disruptions.

Implementation and Benefits

Implementing PdM strategies requires careful planning and execution. A thorough assessment of existing equipment and data infrastructure is essential. Defining clear KPIs (Key Performance Indicators) for measuring the effectiveness of the PdM system is critical for quantifying its impact on overall operational efficiency. Implementing PdM can lead to significant cost savings by reducing unplanned downtime and the need for costly repairs.

The benefits extend beyond cost savings. Predictive maintenance improves operational efficiency by optimizing maintenance schedules and minimizing disruptions. Improved equipment reliability translates into higher output and better productivity. Enhanced safety is another key benefit, as proactive maintenance prevents catastrophic equipment failures that could lead to accidents.

Challenges and Considerations

Despite the numerous benefits, implementing PdM strategies can present challenges. The initial investment in sensors, data analytics platforms, and trained personnel can be substantial. Ensuring data quality and consistency across different equipment types and operating conditions can also be demanding.

Furthermore, integrating PdM with existing maintenance processes and workflows may require adjustments and training. Data security and privacy concerns also need careful consideration to protect sensitive information. Careful planning and a phased approach to implementation are crucial for successfully integrating PdM into the existing infrastructure.

Remote Monitoring and Reduced Operational Costs

Optimizing Maintenance Schedules

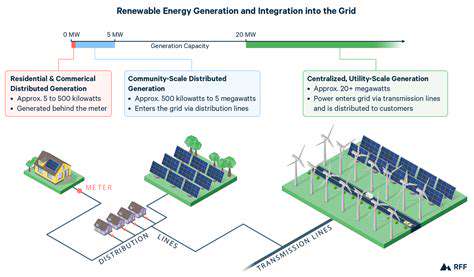

AI-powered remote monitoring systems can analyze vast amounts of data from offshore wind turbines to predict potential failures and optimize maintenance schedules. This proactive approach significantly reduces unplanned downtime, preventing costly repairs and maximizing energy production. By identifying patterns and anomalies in sensor data, AI algorithms can pinpoint equipment that needs attention before it fails, allowing for scheduled maintenance interventions that minimize disruption to operations and improve overall efficiency.

Predictive maintenance using AI not only reduces unexpected downtime but also allows for more strategic scheduling of maintenance crews and resources. This translates to significant cost savings in labor, transportation, and spare parts, all crucial factors in the economic viability of offshore wind farms.

Enhanced Safety and Reduced Risk

Remote monitoring systems equipped with AI algorithms can detect and alert operators to potential safety hazards, such as structural issues, extreme weather conditions, or equipment malfunctions. This early warning system dramatically reduces the risk of accidents and injuries, safeguarding personnel and protecting the integrity of the offshore wind farm infrastructure. Real-time data analysis empowers operators to make informed decisions, mitigating potential risks and promoting a safer work environment.

The ability to monitor critical parameters remotely, coupled with immediate alert systems, drastically reduces the need for frequent physical inspections, which are inherently more dangerous and costly. This translates into a safer and more efficient operation, and also reduces the need for expensive and time-consuming emergency response protocols.

Proactive Issue Identification and Resolution

AI algorithms can analyze data from various sources, including weather patterns, turbine performance, and environmental conditions, to identify potential issues before they escalate into major problems. This proactive approach allows for swift intervention, preventing costly repairs or catastrophic failures. By quickly identifying and addressing anomalies, AI-driven remote monitoring systems contribute to consistent energy output and a longer lifespan for the turbines.

Early identification of issues also allows for the implementation of corrective measures before they impact overall operational efficiency and financial returns. This proactive approach to maintenance, enabled by AI, ultimately translates into significant cost savings and increased profitability in the long run.

AI-driven insights can also provide valuable data for improving turbine designs and operational procedures, leading to further reductions in maintenance costs and an overall enhancement in the performance of the entire offshore wind farm.

This proactive identification and resolution of issues is a key advantage of AI-powered remote monitoring, allowing offshore wind farms to operate more reliably and cost-effectively, and to better adapt to the dynamic conditions of the marine environment.

The ability to pinpoint issues before they become critical is a significant factor in reducing unplanned downtime, maintenance costs, and ultimately, operational expenses for offshore wind farms.

The comprehensive data analysis capabilities of AI algorithms enable a more thorough understanding of the entire system, resulting in more informed decisions and a higher level of operational efficiency.

Future Trends and Innovations in AI-powered Offshore Wind

Emerging Technologies Shaping the Future of A

The future of A is poised for significant transformation, driven by a confluence of emerging technologies. Artificial intelligence (AI) is rapidly evolving, impacting various aspects of A, from personalized experiences to automated processes. This includes advancements in machine learning algorithms, enabling more sophisticated data analysis and predictive capabilities. Furthermore, the integration of AI with other technologies like blockchain and the Internet of Things (IoT) promises to create even more innovative applications within A.

Beyond AI, advancements in virtual and augmented reality (VR/AR) are also set to revolutionize the A landscape. Immersive experiences are becoming more accessible and affordable, opening up new possibilities for training, education, and entertainment within A. These technologies are enabling more engaging and interactive learning environments, leading to increased efficiency and knowledge retention. The integration of VR/AR with other technologies will further enhance these experiences, creating a more dynamic and personalized user journey.

The growing importance of data security and privacy is another critical factor shaping the future of A. With increasing reliance on digital platforms, robust security measures are essential to protect sensitive information. Innovative solutions in cryptography and encryption techniques will be crucial to maintain data integrity and user trust. Moreover, the development of ethical frameworks for AI and data usage will be paramount in ensuring responsible innovation within A.

The Impact on Industries and Consumers

The future of A will undoubtedly impact various industries, driving significant changes in operational processes and consumer expectations. Automation powered by AI will lead to increased efficiency and productivity in sectors like manufacturing and logistics. This will require workforce adaptation and upskilling initiatives to ensure a smooth transition. Furthermore, the personalized experiences facilitated by AI and data analytics will create new opportunities for businesses to cater to individual customer needs.

Consumers will experience a more personalized and seamless experience across various platforms. Tailored recommendations, proactive support, and customized solutions will become the norm, leading to increased customer satisfaction and loyalty. This personalization, however, raises concerns about data privacy and potential bias in algorithms, necessitating careful consideration and responsible implementation.

The overall impact on society will be multifaceted, requiring careful consideration of both the opportunities and challenges. Maintaining a balance between technological advancement and ethical considerations will be critical to ensuring a positive future for A.