The Latest Innovations in Photovoltaic Technology

Perovskite Material Properties: A Deep Dive

Perovskite materials, the cornerstone of these innovative solar cells, exhibit unique optoelectronic properties that make them exceptionally promising. These materials possess a crystal structure resembling that of the naturally occurring mineral perovskite, offering a high degree of tunability in their electronic and optical characteristics. This tunability allows scientists to tailor the material's properties to optimize light absorption, charge transport, and ultimately, energy conversion efficiency. The ability to modify the perovskite structure through variations in composition and processing techniques opens up exciting possibilities for achieving superior performance in various applications.

A key aspect of perovskite materials is their exceptional light absorption capacity. They can absorb a broad spectrum of sunlight, including the portion that is often lost by conventional silicon-based solar cells. This enhanced light absorption translates directly into higher power conversion efficiency. Furthermore, the inherent charge carrier mobility within these materials is considerably high, facilitating the rapid and efficient movement of electrons and holes, crucial for maximizing energy output. The combination of these factors makes perovskite solar cells a compelling alternative to existing technologies.

Fabrication and Processing Techniques: Shaping the Future

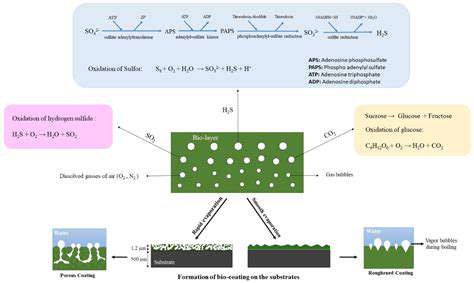

The fabrication of perovskite solar cells involves a series of intricate steps, and advancements in processing techniques are constantly pushing the boundaries of performance. Different deposition methods, such as spin coating, solution processing, and vapor deposition, play a critical role in determining the structure and quality of the perovskite layer. The precise control of these parameters is essential to achieve high-quality films with minimal defects, which directly impacts the overall efficiency of the solar cell. Optimizing these techniques is a significant area of research, aiming to reduce manufacturing costs and increase scalability for large-scale production.

Moreover, the development of new and improved fabrication methods is crucial for achieving high-efficiency perovskite solar cells. This includes strategies for minimizing defects, enhancing charge transport, and improving the stability of the device. Furthermore, the integration of perovskite materials with other components, such as transparent conductive oxides and electron/hole transport layers, is a key focus. Properly integrating these materials is paramount for achieving optimal device performance and long-term reliability.

Challenges and Future Directions: Overcoming Obstacles

Despite their remarkable potential, perovskite solar cells still face certain challenges that need to be addressed before widespread adoption. One major concern is the long-term stability of these devices under various environmental conditions. Exposure to moisture, oxygen, and heat can degrade the performance of perovskite materials, limiting their lifespan. Research efforts are focused on developing protective coatings and encapsulation techniques to enhance the stability and reliability of perovskite solar cells.

Another area of active research is improving the scalability and cost-effectiveness of perovskite solar cell production. Developing low-cost, high-throughput manufacturing processes is essential for making these technologies commercially viable. Scientists are exploring alternative fabrication methods and materials to reduce production costs, making them more competitive with existing solar cell technologies. Ultimately, tackling these challenges will pave the way for wider deployment of this promising solar cell technology.

Furthermore, ongoing research focuses on improving the device's efficiency and stability. Researchers explore diverse strategies to enhance charge collection and minimize energy losses, aiming for higher efficiency and longer lifespan. Exploring new perovskite compositions and optimizing the device architecture are vital steps in this pursuit.

Tandem Solar Cells: Combining Efficiency for Maximum Output

Improving Efficiency in Photovoltaic Systems

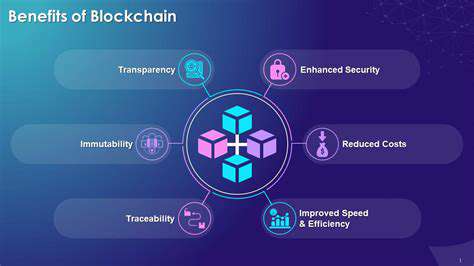

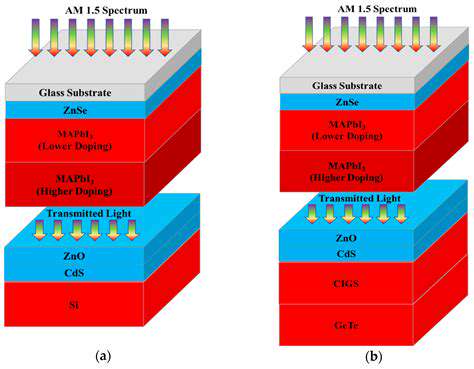

Tandem solar cells, which combine two or more different photovoltaic cells in a single device, are a promising approach for enhancing the efficiency of solar energy conversion. This innovative design allows the system to absorb a broader spectrum of sunlight, capturing energy that would otherwise be lost by a single-junction cell. By carefully selecting the materials for each cell, the tandem structure can achieve efficiencies exceeding those of traditional single-junction cells, representing a significant advancement in the field.

The key to this improvement lies in the complementary absorption characteristics of the different cell materials. Each cell in the tandem structure is optimized to absorb a specific portion of the solar spectrum, working together to maximize energy capture. This synergistic approach is critical for realizing the full potential of solar energy technologies.

Materials Selection and Device Design

The materials used in tandem solar cells are carefully chosen to maximize their absorption of different wavelengths of light. This is crucial because different materials have different absorption properties. Scientists meticulously consider the band gaps of the materials to ensure optimal energy conversion across the solar spectrum. This sophisticated selection process is essential to achieving high efficiency.

Careful engineering of the junction design between the different cells is also vital. This ensures effective charge separation and transport, preventing energy loss. The interfaces between the different materials need to be optimized to minimize recombination of charge carriers. This precise engineering is crucial for the overall performance of the tandem solar cell.

Enhanced Light Absorption

One of the key advantages of tandem solar cells is their ability to absorb a wider range of wavelengths. This is achieved by combining different semiconductor materials with varying band gaps. Each material absorbs different parts of the solar spectrum, allowing for a more comprehensive capture of solar energy. This enhanced light absorption is a critical factor in improving overall conversion efficiency.

By combining the absorption characteristics of two or more materials, tandem solar cells can potentially surpass the efficiency limits of single-junction cells. This increased absorption leads to a significant increase in energy generation, making them a promising technology for future renewable energy systems.

Charge Carrier Management

Efficient charge carrier management is critical in tandem solar cells. The different materials in the tandem structure have different charge carrier mobilities and lifetimes. Careful design ensures that the charge carriers generated in each cell are effectively collected and transported to the external circuit without significant loss. This is achieved through the optimization of the cell interfaces and the use of suitable interconnects.

Cost-Effectiveness and Scalability

The cost-effectiveness and scalability of tandem solar cell technology are important considerations for widespread adoption. Research efforts are focused on developing cost-effective manufacturing processes and materials to reduce production costs. The long-term goal is to make this technology economically viable for large-scale deployment. Furthermore, the scalability of tandem solar cells is crucial for meeting growing energy demands.

Future Research Directions

Future research in tandem solar cells will focus on further improving efficiency, reducing manufacturing costs, and exploring new materials. Researchers are investigating novel materials and architectures to achieve even higher energy conversion efficiencies. This research is essential to unlock the full potential of solar energy for a sustainable future. Further advancements in materials science and device engineering will be necessary to realize the full potential of these technologies.

Flexible and Transparent Solar Cells: Revolutionizing Integration Possibilities

Benefits of Flexible Solar Cells

Flexible solar cells offer a multitude of advantages over traditional rigid panels. Their adaptability allows them to be integrated into a wider range of applications, from clothing and building materials to portable electronics. This flexibility translates into significant design freedom and enables the creation of innovative and aesthetically pleasing products. They also offer improved structural integrity, making them less susceptible to damage during installation or transport compared to fragile glass-based solar panels. Their lightweight nature further enhances their suitability for various installations.

Manufacturing Processes and Materials

The manufacturing process of flexible solar cells often involves the use of thin-film technologies, which employ materials like cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and organic photovoltaic (OPV) materials. These materials are deposited onto flexible substrates, such as polymers or plastics, to create the solar cell structure. The choice of materials and manufacturing process significantly impacts the efficiency and cost of the final product.

Applications in Diverse Fields

Flexible solar cells find applications across a spectrum of industries. They are particularly well-suited for integration into wearable technology and portable devices, providing on-demand power generation. Their lightweight and adaptable nature also makes them ideal for use in building-integrated photovoltaics (BIPV), enabling the seamless integration of solar energy generation into architectural design.

Efficiency and Performance

While the efficiency of flexible solar cells has advanced significantly in recent years, it often lags behind that of traditional rigid panels. However, ongoing research and development efforts are continuously improving performance metrics, aiming to bridge the gap in efficiency. Factors such as material selection, manufacturing techniques, and cell design are crucial elements in optimizing the efficiency and longevity of these solar cells.

Cost-Effectiveness and Scalability

The initial cost of flexible solar cells can sometimes be higher compared to rigid counterparts. However, economies of scale and advancements in manufacturing processes are expected to drive down production costs over time. This will make flexible solar cells more accessible to a wider range of consumers and businesses. Scalability remains a key factor in determining the wider adoption and impact of these technologies.

Environmental Impact and Sustainability

The environmental impact of flexible solar cells is a critical consideration. The use of sustainable and recycled materials in their manufacturing process is essential for minimizing the environmental footprint. Furthermore, the potential for reduced energy consumption in various applications through the integration of flexible solar cells further contributes to the sustainability of these technologies.

Challenges and Future Outlook

Despite their promising potential, flexible solar cells face certain challenges, including durability and long-term performance stability. Further research and development are crucial to address these issues, ensuring the reliability and longevity of these innovative technologies. The future of flexible solar cells hinges on overcoming these hurdles and achieving broader market penetration.

Short coats on pets, whether dogs or cats, offer a unique blend of style and practicality. Their low-maintenance nature is particularly appealing to busy pet owners. The streamlined look often emphasizes the pet's natural physique, highlighting their distinct features. Many short-coated breeds are known for their active and playful personalities, and the short coat allows for easier exercise and play without the added bulk or potential discomfort of longer fur.

Dye-Sensitized Solar Cells: A Cost-Effective Approach for Specific Applications

Dye-Sensitized Solar Cells (DSSCs): An Overview

Dye-sensitized solar cells (DSSCs), also known as Grätzel cells, are a type of photovoltaic device that utilizes a semiconductor photoanode sensitized with a dye to absorb sunlight and convert it into electricity. This unique design offers several advantages over traditional silicon-based solar cells, particularly in terms of cost-effectiveness and flexibility. The use of low-cost materials like titanium dioxide (TiO2) and organic dyes allows for the fabrication of DSSCs at a significantly lower cost than conventional silicon-based solar cells, making them a promising alternative for various applications.

Cost-Effectiveness in Production

One of the key advantages of DSSCs lies in their relatively low manufacturing costs. The use of abundant and inexpensive materials like titanium dioxide and organic dyes significantly reduces the overall production expenses compared to silicon-based solar cells. This cost-effectiveness is a major driver for their potential use in applications where affordability is crucial, such as developing countries or niche markets where solar energy access is limited.

Furthermore, the simpler fabrication process of DSSCs can lead to lower capital expenditure for manufacturers, making them more accessible to smaller businesses and research groups. This accessibility is a key factor in their potential to revolutionize the solar energy sector.

Specific Applications in the Market

Despite their potential, DSSCs are not a universal solution for all solar energy needs. Their efficiency, while improving, still lags behind silicon-based cells in high-power applications. However, their unique properties make them well-suited for specific applications. These include powering small electronic devices, providing supplemental energy to buildings, and integrating into architectural designs.

Performance Characteristics and Efficiency

The efficiency of DSSCs is influenced by several factors, including the type of dye used, the thickness of the photoanode, and the electrolyte composition. While DSSC efficiency can be comparable to or even exceed that of some other types of solar cells in specific lighting conditions, their overall efficiency can be lower than traditional silicon-based solar cells, especially under standard testing conditions.

Ongoing research and development efforts are focused on optimizing these factors to improve the performance and efficiency of DSSCs, enabling them to compete more effectively in various applications.

Environmental Impact and Sustainability

The use of abundant and readily available materials in DSSCs often contributes to a more sustainable approach to solar energy generation. The reduced reliance on rare earth elements and complex manufacturing processes associated with some other solar cell technologies makes DSSCs an environmentally friendly alternative. However, the long-term environmental impact of the materials used in the electrolyte, especially the organic dyes, needs further investigation and careful consideration for a truly sustainable approach.

Materials and Components

The key components of a DSSC include a dye-sensitized titanium dioxide photoanode, an electrolyte, and a counter electrode. The choice of materials for each component plays a critical role in the cell's performance. The use of organic dyes, while often cost-effective, requires careful consideration of their stability and potential environmental impact. Alternative materials are constantly being explored to improve the overall performance and long-term stability of the cells.

Future Research Directions and Advancements

Future research in DSSC technology is focused on enhancing efficiency, improving long-term stability, and exploring new materials for the electrolyte and dye. The development of novel organic dyes with higher light absorption capabilities is a key area of investigation. Further research into the use of transparent or flexible substrates could open up new possibilities for integrating DSSCs into various applications, such as windows and portable devices.

Advanced Solar Cell Manufacturing Techniques: Boosting Production Efficiency

Advanced Thin-Film Deposition Techniques

Thin-film deposition methods are crucial for fabricating high-quality solar cells with improved efficiency. These techniques, such as sputtering, chemical vapor deposition (CVD), and molecular beam epitaxy (MBE), allow for precise control over the thickness and composition of the thin films used in solar cells. This precision is vital for optimizing the absorption of sunlight and minimizing material defects, ultimately boosting the overall performance of the solar cell.

Sputtering, a physical vapor deposition technique, involves bombarding a target material with inert gas ions to create a plasma, which then deposits the material onto the substrate. This method offers excellent control over film thickness and uniformity, contributing to improved solar cell efficiency and reduced production costs. The precise control over film thickness and composition is key to the success of this process.

Perovskite Solar Cell Manufacturing

Perovskite solar cells are a rapidly evolving area of research, promising high power conversion efficiencies. The manufacturing process often involves solution-based methods, which are cost-effective compared to traditional silicon-based approaches. Key steps in perovskite solar cell fabrication include solution processing, spin-coating, and annealing. These steps are essential to create a high-quality, uniform perovskite layer, which is crucial for optimal solar cell performance.

Developing high-throughput methods for perovskite solar cell production is a significant challenge. Researchers are constantly exploring new techniques to improve the reproducibility and scalability of the manufacturing process, which is essential for commercial viability. This innovation is crucial for widespread adoption and integration into renewable energy systems.

Nanostructured Solar Cells

Nanostructuring solar cell materials can significantly enhance light absorption and charge carrier transport. This is achieved by creating intricate nanoscale patterns and structures on the surface of the solar cell. Such structures can enhance light trapping and improve charge collection efficiency. The precise design and fabrication of these nanostructures are critical for achieving optimal performance.

Using nanotechnology allows for the creation of highly efficient solar cells with improved performance compared to traditional flat-surface cells. The ability to control light interaction at the nanoscale is a key advantage that enables a more efficient use of solar energy.

Advanced Characterization Techniques

Accurate characterization of solar cell properties is essential throughout the manufacturing process. Techniques like current-voltage (I-V) measurements, quantum efficiency (QE) measurements, and spectroscopic analysis provide valuable insights into the performance of individual solar cells and the overall manufacturing process. These techniques enable us to identify potential defects or areas for improvement in the production process, allowing for optimization and process control.

Advanced characterization tools provide precise data on the quality and efficiency of the manufactured solar cells. This information is crucial for understanding the performance of the solar cells and for identifying any potential issues related to material quality or manufacturing defects. This data helps in maintaining consistent quality and improving the overall production efficiency.

Scalable Manufacturing Approaches

Scaling up solar cell manufacturing processes is critical for mass production and economic viability. Developing cost-effective and high-throughput manufacturing techniques is a key challenge. This includes optimizing automated processes, reducing material waste, and utilizing roll-to-roll or other large-area deposition methods. These scalable approaches are essential for reducing the production cost and increasing the availability of solar energy.

Significant investment in research and development is needed to create scalable manufacturing processes that can meet the increasing demand for solar energy. Improvements in automation and process optimization are essential for reducing the manufacturing cost and increasing the production rate of high-efficiency solar cells. This will drive the widespread adoption of solar power in various applications.

Materials Optimization for Enhanced Performance

Improving the materials used in solar cells is a crucial aspect of enhancing their performance. This involves developing new materials with higher absorption coefficients, improved charge carrier mobilities, and enhanced stability. The selection and optimization of materials play a vital role in improving the efficiency and longevity of solar cells. Researchers are constantly investigating new materials and optimizing their properties to meet these requirements.

Optimizing the chemical composition and structure of materials within solar cells can lead to significant improvements in their performance. The development of new materials with tailored properties is a continuous endeavor, and this research will continue to drive progress in the field of solar energy. This optimization is essential for cost-effective and sustainable solar energy production.