Understanding the Lifecycle of Renewable Energy Systems

Material Procurement Strategies

A critical aspect of the procurement phase involves developing robust material sourcing strategies. This includes identifying reliable suppliers, negotiating favorable pricing, and establishing clear delivery schedules. Effective procurement strategies minimize project delays and cost overruns, ensuring that materials are readily available when needed throughout the construction process. This meticulous planning extends beyond simply getting the right materials; it encompasses quality control measures to ensure the materials align with project specifications and meet sustainability standards.

Furthermore, procurement strategies should consider factors such as ethical sourcing, environmental impact, and potential supply chain disruptions. This proactive approach helps mitigate risks and fosters long-term project sustainability by considering the entire lifecycle of the materials, not just their immediate use in the construction phase.

Construction Planning and Scheduling

Comprehensive construction planning is essential for managing the project effectively. This involves creating detailed schedules, outlining specific tasks, and allocating resources appropriately. Clear communication channels between project stakeholders, including contractors, engineers, and the client, are vital for successful project execution. A well-defined schedule, meticulously outlining project milestones and deadlines, minimizes delays and ensures the project stays on track.

Site Preparation and Logistics

Proper site preparation is paramount for a smooth construction process. This encompasses tasks like clearing the site, establishing access roads, and ensuring the availability of utilities like water and electricity. Effective logistics management involves coordinating the movement of materials, equipment, and personnel to the construction site efficiently and safely. This includes meticulous planning for potential challenges such as weather disruptions or unexpected site conditions.

Quality Control and Assurance

Implementing rigorous quality control measures throughout the construction process is crucial. This includes regular inspections to ensure that work adheres to specifications and safety standards. Employing qualified personnel and utilizing advanced construction technologies can enhance the quality of the final product. Maintaining meticulous records of all inspections and corrective actions is essential for demonstrating adherence to quality standards and for identifying potential areas for improvement in future projects.

Safety Protocols and Regulations

Adhering to strict safety protocols is paramount in the construction phase. This includes implementing safety procedures for all workers, providing adequate safety equipment, and conducting regular safety training sessions. Complying with relevant local and national regulations related to construction safety is critical to protect workers and prevent accidents. Creating a safe work environment not only minimizes risks but also fosters a positive and productive work culture.

Project Budget Management

Effective budget management is essential for controlling costs throughout the procurement and construction phases. This involves meticulous tracking of expenses, monitoring project progress against the budget, and proactively identifying potential cost overruns. Regular financial reporting and analysis allow for timely adjustments and corrective actions to ensure the project remains within the approved budget. Careful cost monitoring throughout the process helps to prevent financial strain and maintain project viability.

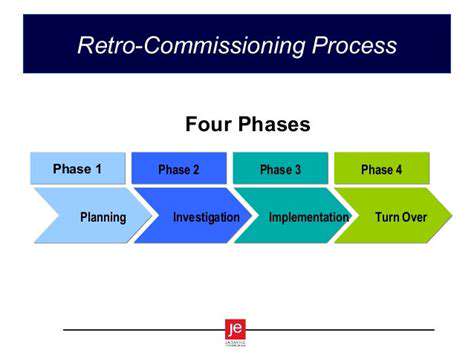

Phase 3: Commissioning and Testing

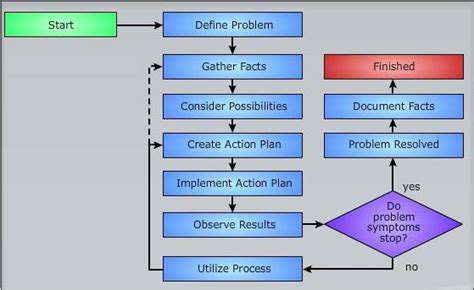

Preparing for Commissioning

The crucial pre-commissioning phase involves meticulous preparation to ensure a smooth and efficient commissioning process. This includes verifying all necessary equipment and supplies are readily available and in good working order. Thorough documentation of all procedures, specifications, and expected outcomes is essential, providing a clear roadmap for the commissioning team. This meticulous planning will minimize potential delays and ensure the project remains on schedule.

Equipment Verification and Calibration

Before connecting and energizing any equipment, rigorous verification and calibration are paramount. This step involves confirming the functionality of all components, checking for any anomalies, and ensuring the equipment meets the required specifications. Calibration ensures accuracy and reliability, directly impacting the performance and safety of the entire system. Proper calibration procedures are critical to the successful operation of the equipment.

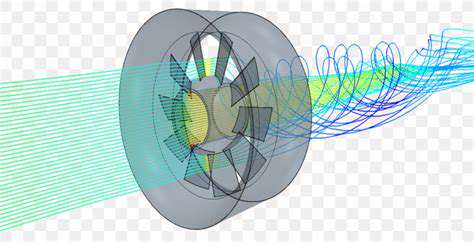

System Integration and Interfacing

System integration is a complex process where individual components are connected and coordinated to form a unified system. This involves careful planning and execution to ensure seamless communication and data flow between different parts of the system. Integration errors can lead to significant delays and potential system failures. Careful attention to detail is paramount to avoid compatibility issues and ensure proper functionality.

Functional Testing

Functional testing is the process of evaluating the system's ability to perform its intended functions. This involves systematically testing each component and the entire system to verify its compliance with established requirements. Extensive testing procedures are necessary to identify and correct any potential issues before the system is put into operational use. Robust testing ensures the system meets the desired performance criteria and minimizes risks of operational failures.

Performance and Safety Testing

Performance testing involves evaluating the system's ability to meet the required performance metrics, such as speed, efficiency, and accuracy. This testing goes beyond basic functionality to ensure the system performs optimally under various operating conditions. Safety testing is equally crucial, aiming to verify the system's compliance with all safety regulations and standards. This involves testing for potential hazards and ensuring appropriate safety measures are in place.

Documentation and Reporting

Comprehensive documentation and reporting are vital throughout the commissioning and testing phase. Detailed records of all testing procedures, results, and any observed deviations from specifications must be meticulously maintained. These records serve as a valuable reference for future maintenance and troubleshooting, and are also crucial for regulatory compliance. Thorough reporting also facilitates communication among the project team and stakeholders.

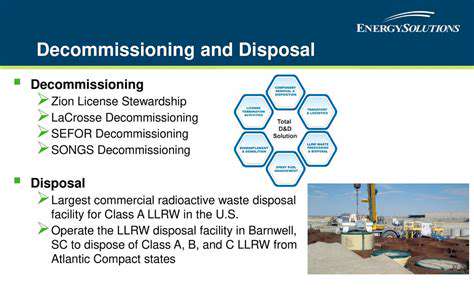

Phase 5: Decommissioning and Disposal

Planning and Preparation

A crucial first step in decommissioning and disposal is meticulous planning. This involves a comprehensive inventory of all assets to be removed, including their specific locations, condition, and potential environmental hazards. Thorough documentation of all procedures and timelines is essential for a smooth and efficient process, ensuring compliance with all relevant regulations. This detailed planning phase sets the stage for a successful and safe decommissioning process.

Careful consideration must be given to the potential environmental impact. Identifying any hazardous materials or substances present is paramount, and appropriate containment and disposal methods must be implemented to prevent contamination of the surrounding environment. A risk assessment is also necessary to anticipate and mitigate any potential safety hazards during the dismantling and removal phases.

Disassembly and Removal

The meticulous disassembly and removal of equipment is a critical aspect of this phase. Specialized tools and techniques may be necessary to safely dismantle complex systems and equipment, ensuring no damage or loss of critical components during the process. Proper handling and packaging of disassembled components are also paramount to prevent damage and ensure the integrity of the materials throughout the process.

This phase demands adherence to strict safety protocols, with trained personnel carefully managing the removal of equipment. Documentation of each step, including photographs and detailed records, will be essential for future reference and accountability.

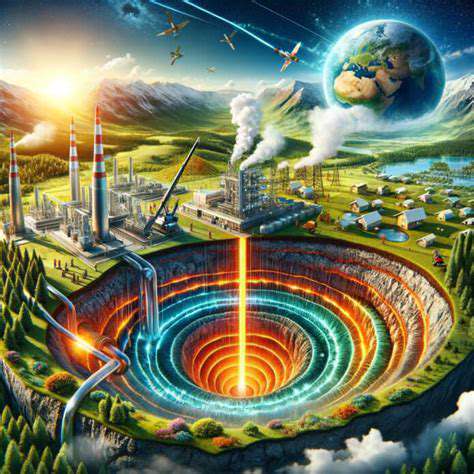

Environmental Management

Environmental protection is paramount during decommissioning. Any hazardous materials must be identified and handled with extreme care, using approved methods for secure storage and transport. This includes comprehensive testing and analysis to confirm the absence of residual contaminants, ensuring compliance with all environmental regulations. Thorough environmental monitoring is essential to ensure no adverse effects on the surrounding area.

Waste management procedures must be strictly adhered to, ensuring appropriate disposal methods for all materials. This includes the proper labeling and segregation of waste according to its type and potential hazard. Maintaining accurate records of all waste generated throughout the process is vital for environmental compliance and accountability.

Regulatory Compliance

Adherence to all applicable regulations is paramount throughout the entire decommissioning process. This includes obtaining necessary permits and approvals from relevant authorities, ensuring that all activities conform to industry standards and environmental guidelines. This strict adherence to regulations is crucial to avoid penalties and maintain a positive environmental impact.

Documentation of regulatory compliance is equally important. Detailed records of permits, approvals, and all steps taken to meet regulatory requirements must be meticulously maintained. This ensures a transparent and auditable process and safeguards against potential legal issues.

Documentation and Closure

Comprehensive documentation is essential for the successful closure of the decommissioning process. Detailed records of all activities, including planning, disassembly, environmental management, and regulatory compliance, must be meticulously maintained. This comprehensive documentation serves as a valuable reference for future projects and ensures accountability. The final report should be a complete record of all actions taken during the decommissioning phase.

Formal closure procedures, including final inspections and the issuance of certificates of completion, are necessary to mark the end of the decommissioning process. This confirms that all tasks have been fulfilled and that the site has been returned to a safe and acceptable condition. This finalized documentation confirms the successful completion of the decommissioning process.