Small Wind Turbines for Residential and Distributed Generation

Introduction to Small Wind Turbines

Understanding the Basics of Small Wind Turbines

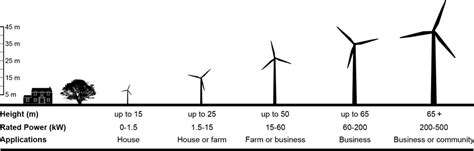

Small wind turbines are a viable option for generating clean, renewable energy at residential and distributed generation sites. They harness the kinetic energy of wind to spin a turbine, converting this mechanical energy into electricity. Understanding their basic components, including the rotor blades, nacelle, and generator, is crucial for comprehending their operation and potential benefits. These systems are typically smaller than utility-scale wind farms and designed for individual homes or smaller-scale energy needs.

Key considerations when evaluating small wind turbines include factors like wind resource assessment in the specific location, the size and type of turbine suitable for the site's wind conditions, and the local regulations regarding installation and permitting. The efficiency of these turbines can vary significantly based on factors like blade design, aerodynamic efficiency, and the amount of wind available.

Assessing Wind Resource Availability and Site Suitability

A crucial step in evaluating the feasibility of a small wind turbine installation is assessing the local wind resource. This involves analyzing historical wind data, wind speed patterns, and the overall wind regime at the proposed site. Factors like terrain, obstructions (trees, buildings), and proximity to bodies of water can significantly impact wind speeds and energy production. Accurate wind resource assessment is essential for selecting the appropriate turbine size and maximizing energy output.

Site suitability is not limited to wind resource analysis. Potential environmental impacts, such as noise levels, visual aesthetics, and wildlife considerations, also need careful evaluation. Compliance with local zoning regulations and permitting requirements is essential for successful installation. A comprehensive site assessment considers all these factors to ensure a successful and environmentally responsible small wind turbine project.

Cost-Effectiveness and Benefits of Small Wind Turbines

The cost-effectiveness of small wind turbines depends on various factors, including the initial investment cost, the long-term operating costs, and the potential for energy savings. These systems can offer substantial cost savings over time by reducing reliance on grid electricity and generating clean, renewable energy. Furthermore, the environmental benefits of using small wind turbines, such as reducing carbon emissions and promoting sustainability, are significant advantages. Understanding the financial incentives and government programs available for renewable energy projects can be crucial to lowering the overall project cost.

Beyond financial and environmental considerations, small wind turbines offer the potential for energy independence and resilience for homeowners and businesses. By generating a portion of their own electricity needs, they can reduce their reliance on the grid, potentially mitigating the impact of power outages and fluctuations in electricity prices. This added level of energy independence and resilience is a significant benefit for many individuals and communities.

Technical Aspects and Types of Small Wind Turbines

Hardware Components

Small-scale manufacturing (SMMA) systems rely on a variety of hardware components, each playing a crucial role in the overall functionality of the system. These components include precision machining tools, automated material handling systems, and advanced sensors for real-time monitoring and control. The integration of these components is critical to achieving high levels of efficiency and accuracy within the manufacturing process.

Different types of SMMA systems may require varying hardware configurations, depending on the specific needs of the production process. For instance, some systems might prioritize high-speed machining, while others emphasize flexibility in material handling to accommodate a wider range of components.

Software Control Systems

Sophisticated software control systems are integral to the operation and optimization of modern SMMA systems. These systems manage the communication between various hardware components, enabling coordinated and automated processes. Accurate and responsive software control is essential for maintaining consistent product quality and throughput.

The use of advanced algorithms and machine learning techniques can further enhance the capabilities of these control systems. These systems can analyze real-time data to predict potential issues and automatically adjust parameters to maintain optimal performance.

Material Handling Mechanisms

Efficient material handling is a critical aspect of any SMMA system. This involves the automated movement of raw materials, intermediate components, and finished products throughout the manufacturing process. Well-designed material handling systems contribute significantly to minimizing downtime and maximizing production output.

The specific material handling mechanisms used will depend on the type of materials being processed and the overall layout of the manufacturing facility. Robotic arms, conveyor belts, and automated storage and retrieval systems are common examples of material handling mechanisms used in SMMA systems.

Precision Machining Tools

Precision machining tools are the heart of any SMMA system focused on producing components with tight tolerances. These tools must be highly accurate and reliable to ensure consistent part quality. Investing in cutting-edge machining tools is essential for achieving the desired level of precision in SMMA operations.

Sensor Integration and Data Acquisition

Sensors play a vital role in SMMA systems by providing real-time feedback on various aspects of the manufacturing process. This data is essential for monitoring machine performance, detecting anomalies, and making necessary adjustments to maintain quality and efficiency. Data acquisition systems must be reliable and capable of processing large volumes of data to maximize the benefits of sensor integration.

Quality Control and Inspection Systems

Integrated quality control and inspection systems are essential for ensuring that products meet the required specifications and standards. These systems often involve automated visual inspection, dimensional measurement, and other types of quality assessments. Reliable quality control is paramount to the success of any SMMA initiative.

Energy Efficiency and Sustainability

Sustainability is increasingly important in manufacturing, and SMMA systems are no exception. Implementing energy-efficient components and processes can significantly reduce the environmental footprint of SMMA operations. Companies are increasingly focused on minimizing their environmental impact, and SMMA systems can play a vital role in this effort. Careful consideration of energy consumption during design and operation is critical.

Maintenance and Long-Term Considerations

Initial Setup and Maintenance

Proper installation is crucial for the long-term performance and safety of any small wind turbine system. This includes careful consideration of the turbine's location, ensuring adequate wind resources, and adhering to all manufacturer specifications during installation. Regular checks should be performed to confirm the integrity of the mounting structure, the security of all connections, and the proper functioning of the turbine's components. This initial setup stage sets the foundation for years of reliable operation.

Routine maintenance tasks, such as cleaning the blades and inspecting for any signs of wear or damage, should be performed regularly. This proactive approach can prevent more significant issues down the road and ensure the turbine operates at peak efficiency. Detailed maintenance schedules and procedures should be meticulously documented for easy reference and to track the turbine's operational history.

Environmental Factors and Durability

Small wind turbines, while designed for residential use, are still exposed to the elements. Understanding the local climate conditions, including wind patterns, temperature fluctuations, and potential for extreme weather events, is essential for selecting a suitable turbine model and ensuring its resilience. Careful consideration of potential corrosion, icing, or other environmental stressors is necessary for long-term durability.

The longevity of the turbine's components, such as the blades, bearings, and electrical systems, is heavily influenced by environmental factors. Selecting materials resistant to corrosion and degradation is vital for maintaining optimal performance and preventing costly replacements or repairs throughout the turbine's lifespan. Proper maintenance procedures should include regular inspections for signs of environmental damage and proactive measures to mitigate potential threats.

Technological Advancements and Upgrades

The field of small wind turbine technology is constantly evolving, with new advancements in materials, design, and control systems emerging regularly. Staying informed about these developments can allow homeowners to potentially upgrade their systems for increased efficiency and performance. Monitoring the performance of the turbine and its output over time can help identify opportunities for improvement and potential upgrades.

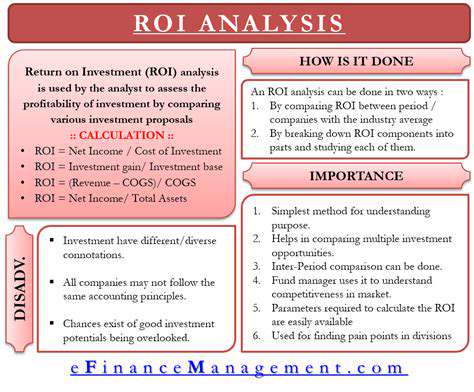

Financial Considerations and Return on Investment

The initial investment in a small wind turbine system can be substantial, but the long-term savings on electricity bills can be significant. Careful financial planning should include an assessment of electricity costs in the area, projected energy production, and potential tax incentives or rebates that may be available. Analyzing the return on investment (ROI) over the turbine's lifespan is critical in assessing the overall financial viability of the project.

Long-term operational costs, including maintenance, repairs, and potential upgrades, should also be factored into the financial picture. Understanding the total cost of ownership is crucial for making informed decisions about the long-term sustainability of the investment and the viability of the system's return on investment.