Innovation in Offshore Wind Installation

Harnessing the Power of the Open Ocean

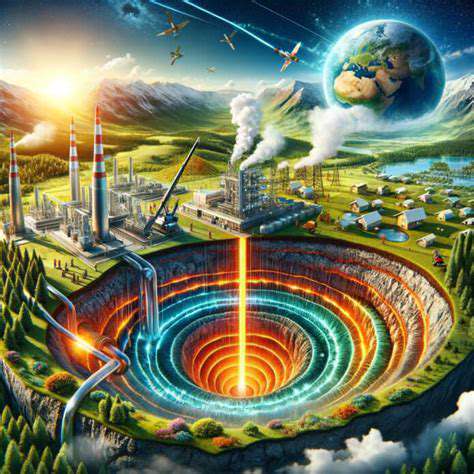

Floating wind farms represent a significant leap forward in offshore wind energy deployment, allowing us to tap into the vast and consistent wind resources available far from shore. Traditional fixed-bottom wind turbines are limited by the depth and seabed conditions of coastal waters. Floating platforms, however, overcome these limitations, enabling the exploitation of deeper waters and potentially higher-quality wind resources, thus expanding the geographic scope of offshore wind energy.

Overcoming the Challenges of Deep Waters

The deeper waters accessible to floating wind farms present both opportunities and challenges. The increased water depth makes the construction and maintenance of these turbines more complex and costly. Specialized vessels and techniques are required for installation and repair, necessitating a dedicated infrastructure for offshore operations. However, the potential rewards—access to stronger and more consistent winds—make these challenges worthwhile.

Technological Advancements Driving Innovation

Several key technological advancements are facilitating the growth of floating wind farms. These innovations include the development of advanced mooring systems, specifically designed to withstand the dynamic forces of the ocean, and the creation of specialized floating platforms capable of withstanding extreme weather conditions. Furthermore, the continuous evolution of turbine design and the improvement in materials science further enhance the efficiency and durability of these structures, making them more resilient in the harsh maritime environment.

Environmental Considerations and Sustainability

The environmental impact of floating wind farms is a critical aspect of their development. Careful consideration must be given to potential effects on marine life, migratory patterns, and the broader ecosystem. Studies and stringent environmental impact assessments are essential to mitigate any adverse consequences. Furthermore, sustainable practices throughout the entire lifecycle of a floating wind farm, from material sourcing to decommissioning, are critical to ensure minimal environmental footprint.

Economic Benefits and Job Creation

The burgeoning floating wind energy sector promises significant economic benefits. The construction, operation, and maintenance of these facilities create numerous jobs in engineering, manufacturing, and related industries. Moreover, the increased energy production can stimulate local economies and contribute to the overall energy security of nations. The potential for export of these technologies and expertise further enhances the economic impact, fostering international collaborations and knowledge sharing.

The Future of Offshore Energy: A Sustainable Vision

Floating wind farms are poised to play a crucial role in the global transition to renewable energy. As the technology matures and costs decline, the deployment of these farms will accelerate, contributing significantly to the decarbonization of the energy sector. This sustainable approach to energy production offers a promising future, reducing reliance on fossil fuels and contributing to a greener planet.

Innovative Installation Vessels and Equipment: Streamlining the Deployment Process

Innovative Design Considerations

Installation vessels, crucial for offshore operations, are undergoing significant transformations, driven by the need for enhanced safety, efficiency, and sustainability. Modern designs prioritize modularity and prefabrication, allowing for quicker assembly and deployment at remote locations. This reduces downtime and minimizes the environmental impact associated with traditional on-site construction. The integration of advanced automation systems further optimizes operational efficiency, reducing human error and improving overall precision.

Key design elements often include optimized hull shapes for improved stability and maneuverability in challenging marine environments. Advanced materials are employed to increase structural integrity and resistance to corrosion, extending the lifespan of the vessel and reducing maintenance needs. Consideration is also given to the vessel's environmental footprint, with designs incorporating features to minimize noise pollution and waste generation.

Advanced Materials and Technologies

The adoption of advanced materials like high-strength steel alloys and composites is revolutionizing installation vessel construction. These materials offer superior strength-to-weight ratios, enabling the creation of lighter, more maneuverable vessels. This translates directly to reduced fuel consumption and emissions, aligning with sustainable practices.

Furthermore, the integration of cutting-edge technologies, such as advanced sensors and real-time data analysis systems, enhances operational safety and efficiency. These systems provide detailed insights into vessel performance, enabling proactive maintenance and minimizing potential risks. Real-time monitoring of critical parameters, coupled with predictive maintenance, ensures optimal vessel performance throughout its operational lifecycle.

Operational Efficiency and Safety

Installation vessels are increasingly designed with operational efficiency in mind. This includes optimized layouts for equipment placement and streamlined workflows, maximizing the utilization of space and personnel. Enhanced safety features, such as advanced collision avoidance systems and reinforced structural designs, are incorporated to mitigate potential risks. This proactive approach to safety prioritizes the well-being of personnel and minimizes the likelihood of accidents.

Remote operation capabilities are also becoming more prevalent. This allows for reduced personnel onboard, which further contributes to safety and efficiency. Remote control of equipment and systems, combined with advanced monitoring systems, provides a safer and more controlled work environment, especially in hazardous offshore conditions.

Environmental Sustainability

The growing emphasis on environmental sustainability is influencing the design and operation of installation vessels. This includes the integration of energy-efficient propulsion systems, such as hybrid or electric options, to reduce emissions and minimize environmental impact. Minimizing the vessel's environmental footprint is paramount in modern offshore operations.

Furthermore, designs are increasingly focused on minimizing waste generation and incorporating advanced water treatment systems to ensure responsible disposal of operational waste. This commitment to responsible environmental practices is crucial for maintaining the long-term health of marine ecosystems and upholding regulatory standards.

Exploring Novel Materials and Construction Techniques for Enhanced Durability

Exploring Novel Materials

Novel materials are rapidly transforming various industries, offering unique properties and functionalities that traditional materials simply cannot match. From lightweight, high-strength composites revolutionizing aerospace engineering to advanced semiconductors driving the next generation of electronics, the exploration of novel materials is a critical area of scientific and technological advancement. The development of these materials often involves sophisticated synthesis techniques and meticulous characterization methods, pushing the boundaries of our understanding of matter and its behavior. This exploration promises groundbreaking solutions to pressing global challenges, from energy production and storage to environmental remediation.

One particularly exciting area of research focuses on materials with enhanced thermal conductivity. These materials could revolutionize everything from cooling systems in electronics to energy transfer in industrial processes. The potential applications for these materials are vast, and their development could lead to significant improvements in efficiency and performance across a wide range of industries. A deeper understanding of the fundamental principles governing heat transfer in these materials will be crucial to unlocking their full potential.

Cons of Novel Materials

While the potential benefits of novel materials are substantial, it's important to acknowledge the associated challenges and potential drawbacks. One significant consideration is the high cost of developing and producing these materials, often requiring specialized equipment and techniques. This cost can make widespread adoption difficult, particularly in applications where affordability is a major concern. Furthermore, potential environmental impacts associated with the production and disposal of novel materials need careful consideration. Minimizing the environmental footprint of these materials is a crucial aspect of their responsible development and use.

Another potential concern is the long-term effects of these materials on human health and the environment. Thorough testing and rigorous safety assessments are essential before widespread deployment. The potential for unforeseen consequences necessitates a cautious and responsible approach to the development and application of novel materials.

Exploring the Future of Novel Materials and Cons

The future of novel materials hinges on addressing the associated challenges while harnessing their potential. Developing sustainable production methods and minimizing environmental impact are paramount. Furthermore, addressing the high initial costs through innovative manufacturing processes and economies of scale will be essential for wider adoption. This careful consideration of the benefits and drawbacks of novel materials is critical for ensuring their responsible and beneficial integration into society.

Ongoing research focusing on the health and safety implications of these materials is crucial. The long-term effects on humans and ecosystems must be thoroughly understood. Detailed understanding of these implications is vital to ensuring the safe and responsible use of these advanced materials.